- Guides

- Posted

The PH+ guide to air source heat pumps

As electricity supply from renewable sources continues to grow, and electricity grids gradually decarbonise as dirtier fossil fuels are phased out, heating homes with electrical technologies like heat pumps starts to make more sense. And in the mild, temperate climate of Britain and Ireland, air source heat pumps are particularly suitable — especially as new build standards of energy efficiency continue to tighten, meaning new homes need less and less energy to achieve comfortable indoor temperatures. But how do air source heat pumps work, what types are there, and how much do they cost to run? Our in-depth guide attempts to answer the key questions.

The electrification of heat maybe something of a slow-burning revolution, but it’s clear that air source heat pumps (ASHPs) will have a big role to play in any mass switch away from fossil-fuel burning heating technologies to renewable ones.

Besides being a very popular choice of heating input in many passive houses and – thanks to Irish building regulations which require both renewable energy technologies and primary energy savings – in Irish new homes, air source heat pumps are catching on in deep retrofit schemes. With generous subsidies available for air source heat pumps and other renewable energy systems in the UK through the Renewable Heat Incentive, and the Irish government’s recently announced €3,500 heat pump grants for Irish homes built before 2006, as well as up to 30% of the cost of heat pumps in non-domestic buildings.

But the potential for air source heat pumps to be used in new build in general is also high, as they can clearly help to meet stringent efficiency and renewable energy targets, including the nZEB requirements that all EU member states – and subject to the Brexit negotiations, the UK – are bound to implement imminently for dwellings and non-domestic buildings.

Advocates insist that the relatively mild climate in the UK and Ireland means that ASHPs are almost as efficient as ground source heat pumps, not to mention cheaper and simpler to install, making it one of the most popular heating system choices for new builds and also for retrofits. Furthermore, a variety of technology upgrades have been introduced over the last few years.

What are heat pumps, and how do they work?

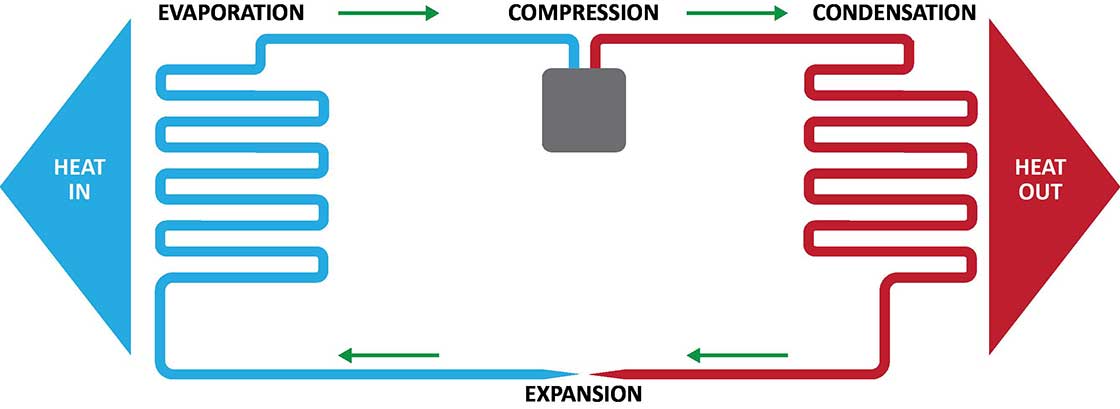

A heat pump is similar to a fridge in the way it works, in that the heat is taken away from the storage section of the fridge and released at the rear. In a heat pump the process is the opposite way round – the heat is taken from the air, ground and water and released into the building.

Any pump needs electricity to run, but it should use far less electrical energy than the heat it produces.

Air source heat pumps extract low temperature heat from the outside air, using refrigerant gases to boost the temperatures to the required levels. Meanwhile ground source and water source heat pumps follow the same principle, instead tapping into the heat energy stored in the ground – either via horizontally laid or vertical borehole collectors - or from bodies of water such as lakes, rivers or streams.

Air temperatures vary seasonally and moisture content fluctuates also, so an air source heat pump will always be at the mercy of the climate. The colder the air temperature, the harder the heat pump must work to lift the temperature up to what is required for heating. What also affects its efficiency when compared with other types of heat pump is the propensity for frost to gather on the collector in colder temperatures. Most ASHPs will have a ‘defrost’ mode to prevent this, but that means it uses more electricity. More on this later.

Types

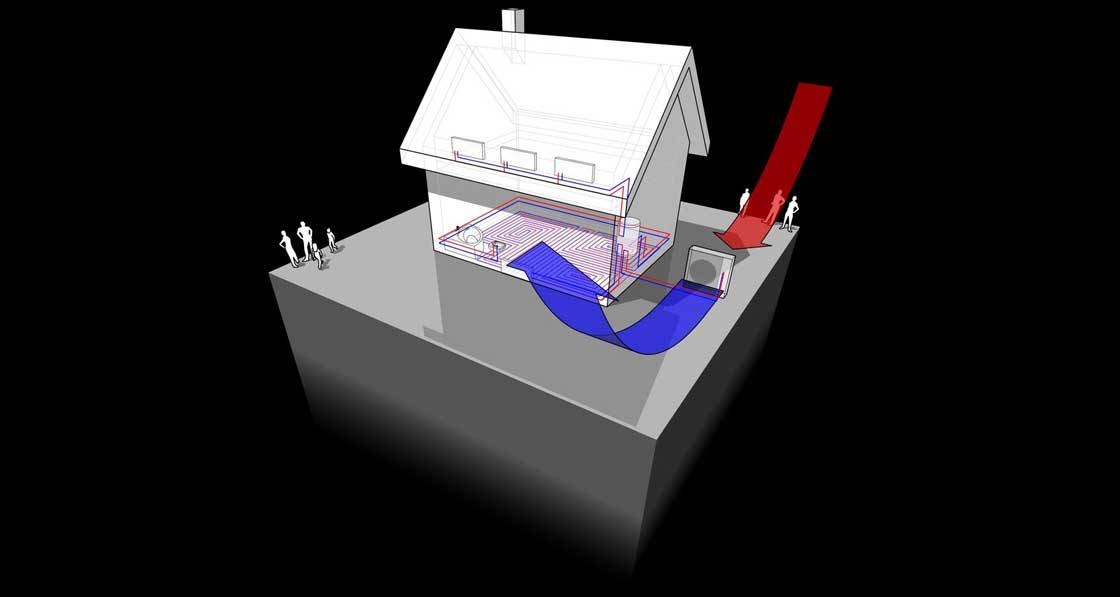

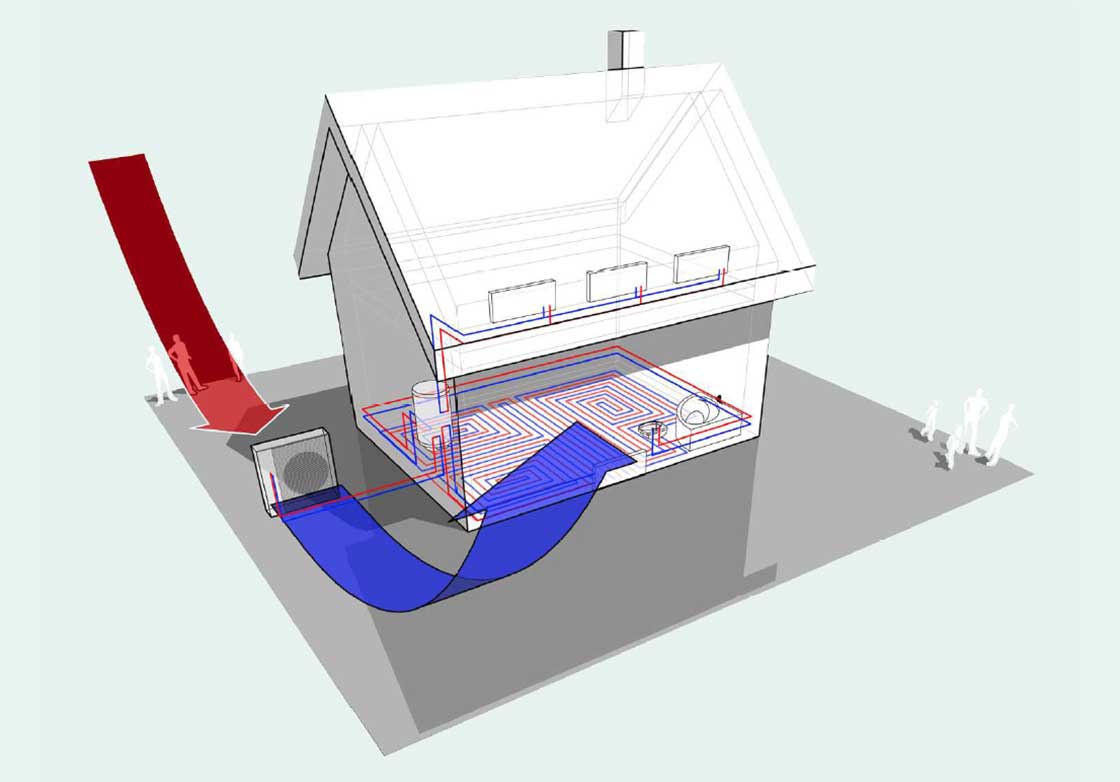

The most common type of ASHP used in dwellings is an air-to-water heat pump, where the refrigerant gas transfers the energy harvested from the air through a heat exchanger, which heats water for heat distribution via underfloor heating or radiators along with domestic hot water.

Exhaust air heat pumps such as the NIBE F730 feature no outdoor unit.

While ASHPs typically take external air as their energy source, one type of ASHP – an exhaust air heat pump – collects energy from warm inside air as it leaves the building via the ventilation system and reuses it for space heating and/or hot water. They are mostly suited to small, highly energy-efficient or passive houses with good ventilation systems.

There are also hot water heat pumps, which can run on 70% less electricity than immersion heaters when used in tandem with a hot water storage tank. Air-to-air heat pumps use the ventilation system to distribute the heat but as the name suggests can’t heat the hot water.

Difference between CoPs and SPFs

The two most widely used values for gauging the efficiency of a heat pump are the Co-efficient of Performance (CoP) and Seasonal Performance Factor (SPF).

The CoP is a simple ratio of the heating provided by a heat pump to the electricity consumed. So a CoP of 3 means that the pump will convert 1kW of electricity into 3kW of heat. Given that the warmer the external heat source, the less electricity it needs to get the heat up to a reasonable temperature, this means that the CoP will vary throughout the year. So the CoP would be lower in the winter months than the summer.

The seasonal performance factor (SPF), however, takes into account how well the heat pump works at both low and high temperatures, while also taking into account additional energy use such as circulation pumps, electric immersion, etc. It is measured as the ratio of the heat delivered to the total electrical energy supplied over the course of a full year, and so is said to be a more accurate measurement of a heat pump’s performance in real world conditions.

An illustration showing the science of how heat pumps work.

Operation and lifespan

Anyone new to heat pumps will need to be educated in how to use them. A typical fossil fuel boiler tends to be cycled on and off, blasting heat at high temperatures into radiators intermittently. The optimum way to operate a heat pump is to keep them ticking over at low temperatures for long periods. Counter-intuitively, it’s a question of leaving the heating on to save energy.

“Yes, people can be puzzled,” says British heat pump consultant John Cantor. “Believe it or not, I had a heating engineer in our cottage who was puzzled. He said the rads are always lukewarm but the cottage is hot. He had not realised that long run hours will bring results. People are rarely patient; slow-response heating is not intuitive when people don’t have a feel for the heat capacity of things.”

If users do end up operating them like boilers, this affects the lifespan of a compressor. A compressor that has a longer run time profile can last around 15 to 20 years compared to a frequently cycled compressor which may need replacing after just six years. A boiler can be cycled on and off without limiting the lifespan of the system. Options to ensure greater longevity can include specifying models with variable outputs, along with buffer tanks.

Excluding exhaust air heat pumps, air-to-water heat pumps feature both an indoor and outdoor unit.

This article was originally published in issue 24 of Passive House Plus magazine. Want immediate access to all back issues and exclusive extra content? Click here to subscribe for as little as €10, or click here to receive the next issue free of charge

Design and sizing is also critical to the lifespan of an ASHP. The size of heat pump should be aligned as closely as possible to a house’s design heat loss, ideally allowing a little spare capacity. But selecting a heat pump that is too big (and many experts says this happens a lot) can lead to it spending too much time trying to run at its minimum setting and prompting more frequent cycling of the system rather than running at a nice steady state at mid-range for long periods.

There is some debate about the suitability of ASHPs in passive houses, with one argument being that it will only operate for space heating when it’s very cold outside. This will affect the CoP, which can also be dented by the many hours it rests on standby power. But since the energy bills are still low, this issue may be overlooked. On the other hand, passive houses are designed in such a way that even in adverse conditions, a steady trickle of extremely low temperature heat may be the ideal way to heat the building.

In terms of where they should be installed, beauty is in the eye of the beholder, but ASHP outdoor units might not look too pretty hanging off a building – and planning could be required if a collector is put at the front of a building. The collectors can be sited close to the building instead, although it’s important that there is enough air circulation around the outdoor unit, as obstructions potentially limit the efficiency of the heat pump. (They’re exposed to ensure they catch the air.)

Monoblocs vs split units

There’s also the issue of whether to use a monobloc or a split unit. Some say that split units, where the heat transference from the refrigerant gas to water takes place inside the building while the collector remains outside, are more efficient than monoblocs, but there are some site-specific issues to consider, so either option – and even each machine – needs to be taken on its own merits.

Monoblocs are generally well suited to the Irish and UK climates; their use would only be an issue in locations that experience prolonged freezing conditions – to be confirmed by manufacturers if anti-freeze is recommended to be used (and therefore the risk of lower CoPs). Even then, as long as the pipes running inside and outside the unit are well insulated, they can be used. Besides being slightly cheaper, monoblocs are easier to install; unlike splits they don’t need specialist, refrigeration technicians to do the pipe work.

Much of the case for using split units seems to depend on the layout of the house and, in the case of a retrofit, whether the whole heating system is being replaced. (For both split and monoblocs, replacing the whole heating system and pipe work should be considered in retrofit scenarios). Situating it in the centre of the house is considered best practice to minimise heat loss and water pipe runs.

Heating distribution

An ASHP will work best with underfloor heating, as it can distribute the heat over a large surface area at temperatures as low as 35C. Standard steel panel and aluminium radiators are typically set up for a flow temperature of 65C but these can also be sized for flow temperatures of 40-45C, as well as fan-assisted rads, ensuring then that higher efficiencies may be achieved. The lower the flow temperature, the higher the SPF.

Tipperary Energy Agency’s SuperHomes nationwide deep retrofit scheme provides compelling evidence. Among other things, the scheme has involved upgrading homes to take ASHPs, while also improving airtightness, insulation and adding energy efficient mechanical ventilation systems – typically demand control ventilation. The heat pumps are connected to the home’s existing radiators, perhaps with a few extra radiators depending on the layout of the house, and are set up to run at very low temperatures almost all the time, taking advantage of the improved heat retention as a result of other measures in the package of options available.

“In principle if we double the time the heating system is in operation, we can halve the temperature difference between the emitter and the room in comparison to an oil or gas boiler,” says Tipperary Energy Agency’s CEO Paul Kenny. “We also increase the duration of the heating system operation that allows the heating system operate really efficiently. Our designs allow the use of about 50 per cent of radiators.”

Cooling

Some air-to-water heat pumps can be reversed to cool buildings, which may be particularly useful in office buildings (though passive cooling from bore holes may tip the balance towards geothermal heat pumps in larger buildings). It’s questionable, though, as to whether cooling is a big issue with most of the housing stock amid our relatively mild climate, though heat waves are likely to become more intense and more frequent as the world warms.

But without due design care, overheating can be a more serious risk in well-insulated and airtight homes– and even in poorly insulated buildings with large expanses of south-facing glazing. In most cases this can be dealt with through brise soleil or shading – and mechanical ventilation can help to shift accumulating hot air – otherwise a heat pump could be used in reverse in conjunction with underfloor heating or wall and ceiling cooling radiant panels, but it’s a complex solution to a problem that could potentially be avoided, with a little design foresight.

Defrost mode

One of the factors that will directly affect the CoP or SPF of an ASHP is if frost occurs in the evaporator. In Ireland this is said to be most likely to occur when the temperatures are between 3 and 8C outside, which means they need to use a defrost mode to prevent the evaporator (collector) icing up, supposedly reducing the CoP by about 10 per cent. In most systems, the heat pump can’t operate in either heating or DHW mode until the evaporator is defrosted. If the heat pump is undersized this may result in a high number of defrost cycles which reduces the efficiency of the heat pump, meaning the system underperforms.

However, according to Seamus Hoyne of Limerick Institute of Technology, which has been monitoring 20 SuperHomes since April this year as part of the SuperHomes 2.0 research project on optimising the performance of ASHPs, the energy ‘drain’ caused by the defrost mode has been negligible.

Detailed data from November 2016 seen by Passive House Plus for one SuperHomes house in Tipperary showed that the defrost mode was used 0.4% of the time, totalling 2% of the monthly running costs. The average local temperature that month was 5.1C, with relatively low rainfall levels.

Lower cost systems offer only a rudimentary control of frost build-up, and tend to have a reduced SPF because of it, but newer systems reportedly work much better. Some machines will simply increase the fan speed in conditions when condensation is occurring to stop the collector from icing up. An emerging technology is a ‘dual evaporator’ that allows for defrosting whilst continuously supplying heat.

Connections to other heat sources

Aside from oil boiler companies moving into heat pumps (such as Firebird Heating Solutions and Grant, among others) and selling them with oil boilers as a back-up that kick in during sub-zero conditions, heat pumps can be paired with existing and other energy sources.

With the internet of things, some heat pumps can talk to solar PV systems, so that they come on when the PV array is generating more electricity. They can also be combined with solar thermal, biomass boilers and heat recovery ventilation systems.

Typical capital costs

The typical starting capital cost of a reputable ASHP (excluding the cost of the heating distribution system or installation) for a 200 sqm house would be in the region of €8,000 excluding VAT, while a scheme of 100 sqm houses might be able to get one for €5,000.

Typical running costs

Helpfully, SEAI’s comparison of the energy costs of domestic fuels recently includes a section on electricity used by heat pumps. Its figures for July 2017 show that heat pumps with high SPFs are clearly the cheapest form of heating in Ireland. Heat pumps with a listed average SPF of 4, (day rate electricity band DD) cost 4.98 cent per kWh and on night rate, just 2.28 cent per kWh. An oil boiler burning kerosene at 70 per cent efficiency – as assumed in SEAI’s Deap software for boilers for homes built between 1985 and 1997 – would cost 10.09 cent per kWh, making a relatively high SPF heat pump less than half the running cost of oil, even before night rate electricity is considered.

The picture’s similar with natural gas: a 72% efficient gas boiler (the assumption for pre ‘98 boilers in Deap) would cost 11.51 cent per kilowatt in band D1 (below 5,556 kWh/yr) or 9.42 cent in band D2 (from 5,556 to 55,566 kWh/yr).

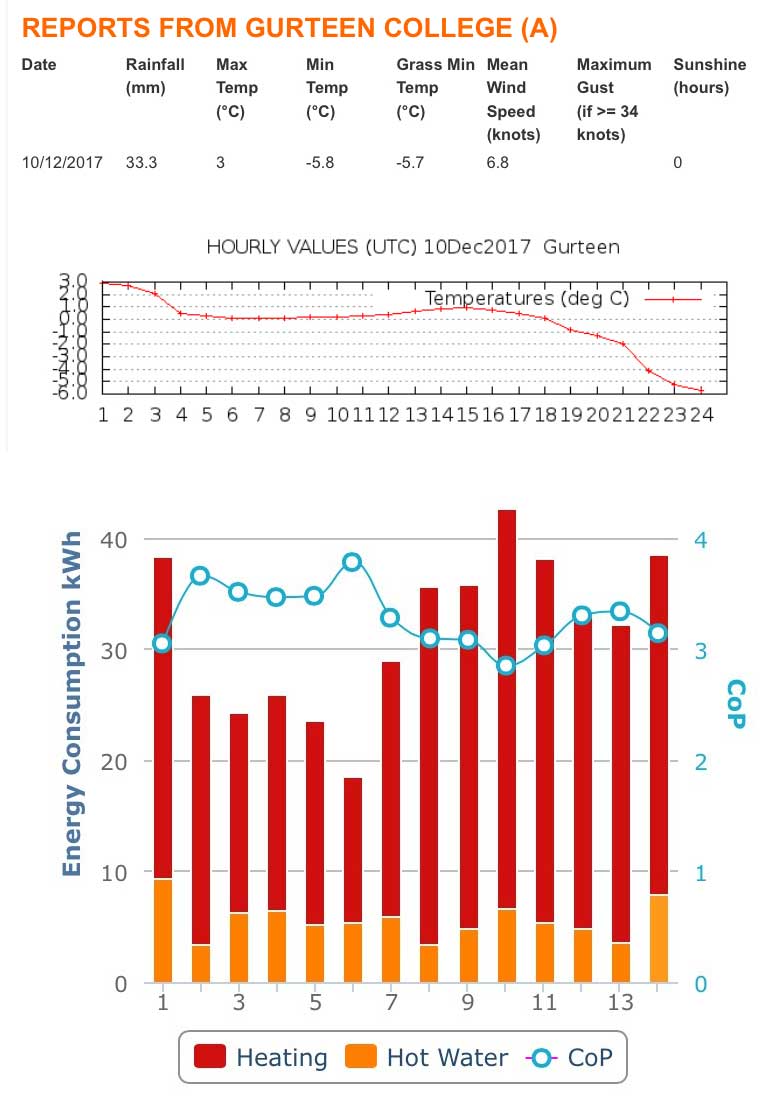

Monitored COP data for Paul Kenny’s heat pump during the cold snap in December 2017, alongside local weather data for the coldest day in that period, 10 December. The heat pump dropped just below a CoP of 3 on the coldest day.

It’s also worth noting that SEAI’s figures are punitive towards heat pumps, in that they build standing charges into the unit costs. The point is that those standing charges would be incurred irrespective of whether a heat pump was installed, due to the normal electrical use.

Conversely this is a fair approach in the case of natural gas, as the standing charge relates directly to heating and hot water and little else.

After all, if households don’t have gas-based heating and hot water they’re highly unlikely to maintain a gas supply for cooking, which surely wouldn’t justify the standing charges on its own. And once standing charges are removed from the electricity prices, an even wider gap emerges. Based on the cheapest electricity tariff currently listed on Irish price comparison site Bonkers.ie and an SPF of 4, the heat pump running costs drop to 3.63 cent at day rate and just 1.74 cent at night rate. The figures still look impressive at a much more modest SPF of 3: a day rate of 4.84 and night rate of 2.32 cent respectively.

But what about data on real world performance? Passive House Plus readers may recall countless examples of low energy buildings with impressively low ASHP running costs – including figures as low as €170 per annum for heating and hot water for semi-detached family homes (see panel) – though it’s worth emphasizing that in the case of passive houses, most of the heavy lifting regarding space heating is done by the sheer efficiency of the buildings.

There are also promising signs emerging from the SuperHomes 2.0 project, which includes monitoring of 20 air-to-water heat pumps. Though the 77 SuperHomes retrofits done to date have included a broad range of heat pumps – CTC, Dimplex, Daikin, Hitachi, Mitsubishi, Nibe, Panasonic and Samsung – the monitoring study consisted almost entirely of Mitsubishi units, given that most other units didn’t have suitable monitoring systems in place for project commencement in April 2017. Based on the data collected from April till the end of November 2017, the average seasonal CoP – for both space heating and domestic hot water – is between 3.2 and 3.5, while the average SPF – allowing for immersion use, defrost mode, etc. – is between 3.0 and 3.2. A fuller picture will appear once twelve months of data has been gathered – including winter performance – but the signs are that the average SPFs in this study will be substantially better than the average for ASHPs of 2.45 registered by the Energy Saving Trust in 2013.

Data from Paul Kenny’s heat pump during the cold snap in early December provides further encouragement. Between 1 and 13 December the CoP averaged for heating and hot water only dropped a little below 3 on one day, 10 December, when temperatures dropped to nearly -6C. “From Sunday to Tuesday we had three inches of snow lying on the ground and a very hard ground frost overnight,” says Kenny.

Night rate meters

Most heat pump installations reportedly run on a mix of day rate and the cheaper night rate electricity. It would certainly appear to make sense to run air-to-water heat pumps at night, even when temperatures are likely to be lower (and thus the CoP) and even if the standing charge is a bit higher. If you use night rate electricity to generate hot water at night, and to run dish washers, washing machines etc., then so much the better.

But do night rate meters go far enough?

Seamus Hoyne of LIT says that as part of the research into optimising the performance of heat pumps, it is looking at the feasibility of a heat pump tariff in conjunction with Electric Ireland and ESB Networks if much of the load of heat pumps could be shifted away from peak times.

In theory, smart grid technology could be connected to intelligent controls at heat pumps so that heat pumps (and other appliances that aren’t required to be on immediately at any given time) can be turned off and on depending on energy supply vs. demand. This could also help mitigate any potential issues with power outages.

Tipperary Energy Agency CEO Paul Kenny, who runs the SuperHomes scheme, has availed of a SuperHomes retrofit himself – including heat pump, PV array and a fabric upgrade – and is making good use of the night rate tariff, with 55% of his total household electricity consumption at night rate. But most people, it seems, are less likely to try and avoid the higher tariff.

The indicative average, according to Hoyne, is 30 to 35% night rate to run heat pumps across the monitored homes.

Primary energy

While heat pumps are clearly greener than oil or gas boilers, their true greenness does, of course, depend on the source of the electricity generation that powers it. So the same heat pump may have very different ratings based on the electricity mix in whichever country it’s installed in, and also on when it was installed. For example, in Ireland the primary energy factor for grid electricity used in Deap (and thus for BERs and Part L compliance) was 2.7 up until 2006, meaning 1kW used to power a heat pump was regarded as 2.7kW at the power station. It has fallen progressively since SEAI started updating the figure in 2010, and is now 2.08 – a 23% drop. Meanwhile, the carbon intensity figures have fallen by an even greater margin of 36.4%, from 0.643 to 0.409 kg/kWh. In the UK, similar improvements are apparent between the still current SAP 2012 software, and the proposed SAP 2016. The primary energy factor is proposed to drop from 3.069 to 2.364, with the carbon intensity dropping from 0.519 to 0.398 kg/kWh.

Given the commitments Ireland and the UK have made to increase renewable electricity generation in the short, medium and long-term, these figures are bound to keep dropping, meaning the energy and carbon figures for buildings heated by electrical sources are bound to keep improving over time.

However, while primary energy figures have been dropping, the cost per unit of delivered energy (i.e. the energy registered at the meter) in Ireland has risen by around 20% since 2010. All of which really means that in the case of working out the running costs of a heat pump, it’s the amount of delivered energy required to run it that really counts – and the cost per unit of electricity (both current and projected).

Challenging assumptions on heating profiles

In some types of buildings in Ireland at least, there’s evidence to suggest that space heating use may be peaking not during the coldest times of the year, but in the so-called shoulder months, a theory put forward by consulting engineer Paul Overy noted in issue 1 of Passive House Plus.

Having mapped out a year’s worth of weather files including hourly readings for Birr, Co Offaly, Overy found a clear correlation: once temperatures drop below 4C or so, there’s a clear and progressive drop in wind speeds. The article posited a few possible contributing explanations: heat loss caused by infiltration, poor wind-tightness meaning wind whipping heat out from insulation, and occupant’s turning up the thermostat due to the discomfort caused by draughts. This leads to a couple of pertinent conclusions. Airtightness and wind-tightness rise in significance, while heating demand may be peaking in ideal weather for air source heat pumps – and at the precise times when more wind energy may be available, which in turn means the real-time primary energy of electricity used by ASHPs may be better than the annualised average.

Hot water production

The typical CoP of air source heat pumps for domestic hot water (DHW) generation seems to be lower than for space heating, often struggling to get above 3, even in the summer. “My feeling is that nobody is pushing the manufacturers to improve matters here,” says John Cantor.

To ensure a system has hot water on demand, how you set it will be crucial. For instance, you could set the timer so that the heat pump heats DHW only in say, two time periods a day. At the start of the day’s hot water heating when the cylinder bottom is quite cold, the initial start may have a CoP of 4. This may have dropped to 2 by the time it has reached 55C, but the average would be quite good, says Cantor.

Immersion use

Most heat pumps come with inbuilt immersions, ostensibly as a back-up and used only as a last resort as long as the system is properly designed, sized and installed, according to those in the trade.

They may be used to bring the water temperature up higher for DHW in certain circumstances or to “flash” the water up to 55 or 60C say, once a week, to prevent legionella from occurring. But lots of ASHP companies say the immersion is never used. The average SPFs – which include immersion use – of 3 to 3.2 reported so far in the SuperHomes retrofit study indicate that the immersion use in well-designed systems should be negligible, meaning a potentially significant reduction on energy bills. According to Electric Ireland, the average Irish household spends about €1.30 per day - €475 per year - on electric immersion use for domestic hot water.

Which? Magazine estimates the immersion use in a typical UK house to be “at least £360 a year”.

One alternative to built-in immersion is a desuperheater, which is a small, auxiliary heat exchanger that uses superheated gases from the heat pump’s compressor to heat water. “A desuperheater is a great add-on to a heat pump system giving a small percentage of the output at a high temperature for domestic hot water needs”, says Dr Niall Burke of Athlone Institute of Technology, who did his PhD on heat pumps.

Others, however, believe that the key to minimal use of the immersion is longer or even constant use cycles at low temperatures. Not all in-built immersions are equal, it seems. “The cruder ones can ‘panic’ and switch on the immersion far too eagerly. It can take a little skill to set the system up to avoid this,” says Cantor.

Controls

There is some debate about whether or not heat pumps work best when there aren’t too many ‘zones’. Many folks prefer their bedrooms to be cooler than their living rooms, and in some passive houses, their owners have opted not to include underfloor heating in bedrooms to facilitate this. However, some say that fitting too many room thermostats can confuse a heat pump controller, leading to more cycling on and off, leading to higher running costs and reducing lifespan. A buffer tank may be needed if this is the case.

Large low maintenance nZEB house

Heat pump running costs: €170/yr

Completed in February 2015, this 389 sqm family home was built by experienced passive house contractors Mannion Passive House Builders, and features a Nibe F2040 12kW air-to-water heat pump.

Homeowners Sinead and John have been maintaining the house at a minimum of 21C, and the monitored heat pump energy use has been just 1,445 kWh per year for space heating and 2,213 kWh for hot water – meaning that if just 30% of the energy is used at night rate, the heat pump’s annual combined space heating and hot water costs would be just €170 – excluding whatever additional energy use may come from the home’s gas fire and wood stove. What’s more the homeowners could hardly be accused of micro-managing the heat pump to optimise performance. “I don’t even know it’s there,” Sinead told Passive House Plus. “I never have to turn it off or turn it on.”

The house, which was featured in issue 21 of Passive House Plus, scored a mid A2 BER, and comfortably beat the energy and carbon targets for Ireland’s forthcoming nearly zero energy building standard.

SuperHomes cost-optimal retrofit

Heat pump running costs: €491/yr

The home of Tipperary Energy Agency CEO Paul Kenny used to be an energy guzzler. Having upgraded and sold his previous home, Kenny and his wife Norah bought a 225 sqm house in Newtown, Co Tipperary, to accommodate their growing family, but were braced for the worst.

“The previous tenant had moved out as the house was too cold,” says Kenny. “She said she used four tanks of oil and a bag of coal a week and it was still freezing!” Kenny duly had the home’s cavity walls pumped with insulation before moving in, but it wasn’t enough: “The day we got the keys storm Darwin hit and the house leaked so much the curtains shook.” Kenny spent the following spring sealing the window frames.

Pre upgrade, the BER for the 2005 home was a B3, with a total calculated primary energy use of 129 kWh/m2/yr. Heated by home heating oil, the house cost the family €2,228 to heat in 2014 in spite of Kenny’s cavity insulation and window sealing, between running the oil boiler and wood fuel. As is so often the case with such buildings, that was in spite of the home being uncomfortably cold at times.

Kenny, who set up the SuperHomes scheme at TEA, availed of a SuperHomes retrofit himself – including a Mitsubishi air-to-water heat pump, PV array, Aereco demand controlled ventilation and a fabric upgrade at a total cost of €19,500, or €12,650 after the grant. The project was an early test of the SuperHomes approach of well-considered, cost-effective measures: insulate, remove draughts and ventilate intelligently to ensure good indoor air quality while reducing ventilation heat loss, to create the conditions where a heat pump could be attached to the existing rads – with some additional rads if necessary – and run for long stretches at low flow temperatures. The reported results are impressive: Kenny’s heat pump clocked a combined total of 4,739 kWh for space heating and hot water in 2017. Assuming the current lowest electricity price from price comparison site Bonkers.ie that adds up to €491, along with an estimated €75 worth of wood fuel.

Other than the efficiency of the building, the heat pump is aided by Kenny’s PV array, which produces 1,700 kWh of electricity – 100 kWh of which is exported to the grid for nothing, given the lack of micro generation incentives in Ireland. Kenny has measured that 460 kWh is dumped into the immersion, displacing a little night rate electricity, while Kenny estimates that the remaining 1,140 kWh is split roughly 50/50 between household electricity use and powering the heat pump, worth €82 in each case.

But this undersells the benefit. The house is now running at a consistent 20+C, which is very different to the under-heated house he had before. He has calculated that attempting to heat the original building to the same comfort level – and in reality this would have caused the building to constantly fluctuate between too cold and too hot - would have added €864 to his 2014 energy bills.

Against this scenario, the retrofit is delivering a whopping €2,500 saving per year. Depending on whether the 2014 or current low oil prices are used, and on whether the house is compared against an under-heated or 20+C house, the estimated payback ranges from 5 to almost 11 years.

1060s semi-d passive house retrofit

Heat pump running costs: €190/yr

When Ciaran Ryan and Mary Hodkinson went house hunting in Galway they were so committed to deep retrofit that they asked an architect friend – Passive House Plus columnist Simon McGuinness – to help pick a house that might lend itself to the process. Designed by McGuinness, the eventual retrofit to a 1960s semi-d in the Galway suburbs is about as radical as a retrofit gets: the 142 sqm house was gutted, reconfigured and upgraded to full certified passive house status in the process.

The upgraded house is solely reliant on a Thermia air-to-water heat pump for space heating and hot water, installed by low energy specialists Heat Doc.

While passive houses tend to have unusually low running costs, the measured energy use in this house is nonetheless impressive. The metred usage for Ciaran, Mary and their two grown-up children in the home’s first year (or year and three weeks, more precisely) post retrofit was just 3,658 kWh – 1,445 kWh for space heating, and 2,213 kWh for hot water.

The house, which was featured in detail in issue 11 of Passive House Plus, cost an estimated €190 for heating and hot water in its first year. While the space heating part of that is an eye-wateringly low €55, such a figure owes greatly to the building’s extremely energy efficient fabric. In this case it’s arguably the hot water production where the heat pump earns its stripes – and a cost of €127 per year and €7 of immersion use isn’t too shabby.

With thanks to

Dr Niall Burke, Athlone Institute of Technology | John Cantor, heat pump consultant | Damien Mullens, Heat Doc | Calin Tasnadi, Heat Pump Association of Ireland | Paul Kenny, Tipperary Energy Agency | Seamus Hoyne, Limerick Institute of Technology | Richard Sherlock, Mitsubishi Electric | Brian Cooley, Climate Control Renewables Ltd

Additional reporting by Jeff Colley