- Help desk

- Posted

Fire compartmentation & timber framed party walls

In this Help Desk I will be returning to the issue of compartmentation at party (separating) walls in residential construction. This time, on the request of several readers, I will look at timber framed party wall construction, which presents unique challenges.

The underlying principal of timber framed party wall (or “separating” wall) construction is that two entirely separate walls are required with an air gap between them. Each individual leaf is designed to contain the fire within its own compartment for a period of at least 60 minutes.

Once the fire-resistant wall facing is breached by the fire, the exposed timber framing behind burns rapidly. Sixty minutes is assumed to be sufficient time to evacuate the compartment which is on fire and for the emergency services to contain the blaze. Most of these separating wall structures are designed to meet the performance required without additional margin. When there is no margin for error, particular attention is warranted to ensure the performance required is achieved.

In this form of construction, heavy reliance is placed on a near continuous fire resistant plasterboard facing to each leaf of the party wall. This facing is made up of two boards, typically a 19mm board tight against the stud and a 12mm board facing the room. Care must be taken to ensure that the joints between boards are overlapped in both directions by at least 600mm to avoid concurrent joints allowing fire to breach the facing. All plasterboard edges in this wall must be fully supported by vertical or horizontal framing (studs or noggins) to prevent delamination of the plasterboard layers under fire conditions. Joints must usually be taped and filled, even in the attic area, in order to achieve the tested fire performance of the double board lining.

This article was originally published in issue 23 of Passive House Plus magazine. Want immediate access to all back issues and exclusive extra content? Click here to subscribe for as little as €10, or click here to receive the next issue free of charge

The party wall is often a loadbearing structural element which means that floor joists penetrate the facing to rest on the timber frame behind. This introduces a weakness which requires additional measures to prevent smoke and flames entering the cavity between the two leaves. Similarly, it may be constructed in above-ceiling and below-ceiling sections requiring jointing details which also need particular fire-stopping. In this article, I will concentrate on the roof-to-wall junction as this continues to be problematic, mainly due to the complex coordination of responsibilities involved. If prompted by readers, I will deal with the other abutments of the party wall in future articles.

The assumption that the fire test of the linings is sufficient to determine the compartmentation standard of the wall rests on the faulty presumption that the plasterboard facings are continuous and extend up to the underside of the roof tile or slate without any gaps.

They don’t: the wall stops below the sarking layer which leaves a gap above it. Rafter alignment may introduce another gap below the sarking also. Those two gaps must be closed with mineral wool. To support the mineral wool, it is first necessary to install a non-combustible cavity closer board joining the top of the two leaves of the party wall.

Filling the residual gap between the non-combustible closer board and the underside of the roof tile/slate is a two-stage process, each stage of which may fall to a different contractor. The lower layer must be in place before the sarking is installed, whilst the upper layer is installed as part of the roof tiling/slating process. This creates a coordination problem: each of the mineral wool layers will be installed by different subcontractors, often weeks apart.

The resulting mineral wool ‘sandwich’ will close the gap between the top of the party wall and the underside of the roof tiles/slates. This ‘sandwich’ should be a little wider than the party wall it sits on and extend over the ridge from back of fascia on both sides of the roof. It also performs the very important function of measurably reducing the thermal bridge at the top of the party wall.

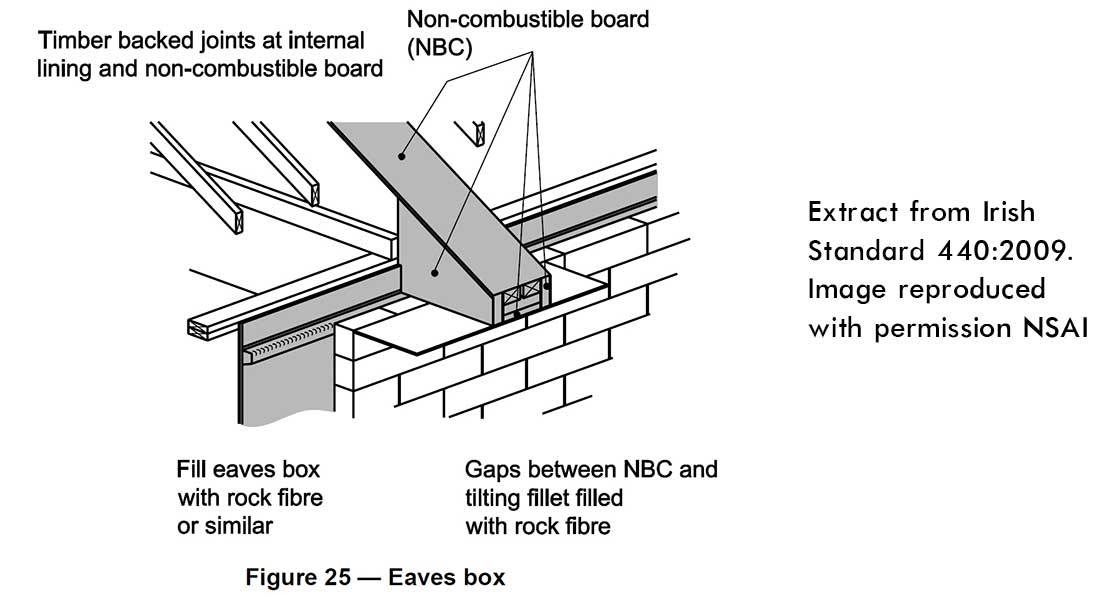

There is yet a further complexity relating to the eaves condition: closing off the overhanging eaves cavity. An extension of the party wall, called the “eaves box”, is recommended for this in Irish Standard I.S. 440: 2009, ‘Timber frame construction, dwellings and other buildings’.

This eaves box is the same width as the party wall and completely fills the space between the fascia, soffit, external wall and the roof covering, see Figure 25 at top. This is a time-consuming piece of bespoke carpentry to construct on site, which needs to be free of any gap which might permit the passage of smoke.

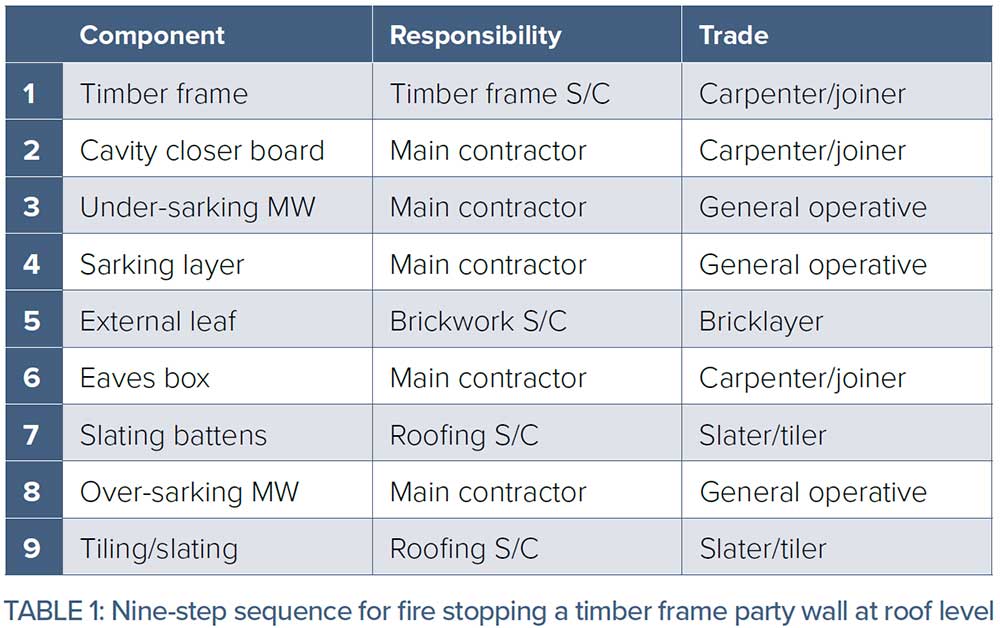

Table 1 summarises the nine sequential steps involved in adequately firestopping a timber framed party wall at roof level. This may involve supervising the work of seven different people. Its importance, and the management challenge it presents to specifiers, contractors and certifiers, should not be underestimated.

Have a question you want to put to the help desk?

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Please note that personal correspondence cannot be entered into.