Chris Morgan

Chris Morgan

- Feature

- Posted

Flat earth

What do you do when a building type is inefficient, common, hard to treat – and often used to house vulnerable people? Chris Morgan of leading passive house architects John Gilbert Architects tells the story of an extraordinary pilot project that may show the way to solve the stickiest of problems.

Click here for project specs and suppliers

Building type: Victorian sandstone tenement with eight one-bed flats – each circa 49 m2

Method: Mix of internal and external insulation, hygrothermal simulation, thermal bridging calculations, heat recovery ventilation, mix of air-to-water heat pump and gas boilers

Location: Niddrie Road, Glasgow

Standard: Near Enerphit

Space heating cost: Too soon to say definitively – monitoring is ongoing

Built around 1900, the building at 107 Niddrie Road is a stone tenement consisting of eight one-bedroom flats over four storeys, located in the inner south side of the city. Southside Housing Association (SHA) approached John Gilbert Architects (JGA) to look at refurbishing the building. Unusually, SHA owned all the flats in the close and, even more unusually, all flats were empty.

This presented an almost unique opportunity to undertake a much more comprehensive refurbishment than is normally possible.

The project was conceived before the Passive House Institute developed its Enerphit unit pilot project, which enables certification of individual flats within a building. To achieve the standard, the whole block would need to be upgraded. For this reason, JGA proposed an Enerphit level retrofit, along with two other, less rigorous options.

Initially, it was decided to pursue a relatively conventional retrofit. However, a consortium including SHA and JGA along with the UK Collaborative Centre for Housing Evidence (CaCHE) at the University of Glasgow, and Prof. Tim Sharpe at the University of Strathclyde Department of Architecture, were successful in bidding for a significant tranche of funding from the Scottish Funding Council to disseminate best practice in retrofit ahead of the 2021 COP Climate summit in Glasgow.

The project was upgraded to an Enerphit project and re-cast as an exemplar of what to do with the 75,000 iconic pre-1919 sandstone tenements across Glasgow. The age, built form, condition and multiple forms of ownership of these tenements constitute major challenges for the achievement of net zero emission targets across Scotland. To ensure wider lessons were learnt from the project, the project has been evaluated and monitored to assess the success of the strategies employed.

Although passive house and Enerphit tend to be considered as focussing primarily on energy efficiency and closing the performance gap, we were keen to demonstrate a range of wider potential benefits that include health and comfort improvements for occupants, as well as showing how such high performance requirements can be integrated with health, climate change adaptation and heritage considerations.

Retrofit measures

If the whole building is to be tested, the airtightness layer across the whole building should be accessible at the same time.

The diagram shows the basic measures that were put in place. Insulation and airtightness in the roof and beneath the floor were installed as normal, although of course much more effort was needed to close off the thermal bridges at the junctions with the walls. We opted to form an airtight layer on the inside of all external walls using lime plaster.

This allowed us to avoid potential thermal bypass and air leakage ‘at source’ and felt like a more suitable way of achieving the modern concept of airtightness with a traditional technique.

External wall insulation was proposed for the rear (South) elevation as well as the partially obscured gable elevation, as these were considered less important than the street elevation from a planning and conservation perspective. Although there was some initial resistance from the planning department, it was all eventually agreed. Because of the rigours of Enerphit and the relatively low levels of insulation on the street side, we had to increase the thickness of external insulation to 200 mm, with attendant issues for reveals, cills and fixings generally.

Window openings on the south side of the building were enlarged slightly (central stone mullions were removed) to increase solar gain. Planning insisted on a central timber mullion in all of these windows to visually ‘replace’ the mullion we had removed, which reduced the benefits of the new triple glazed windows somewhat, and we were also obliged to install ‘mock’ oversized cills to mimic the stone cills that were being covered up.

-

To begin, with the idea was simply to strip back the external walls of each room. One of the bay windows to the front of the building

To begin, with the idea was simply to strip back the external walls of each room. One of the bay windows to the front of the building

To begin, with the idea was simply to strip back the external walls of each room. One of the bay windows to the front of the building

To begin, with the idea was simply to strip back the external walls of each room. One of the bay windows to the front of the building

-

At the ground floor, there was one area where the joists were rotten and were replaced, and masonry columns were strengthened with new brickwork

At the ground floor, there was one area where the joists were rotten and were replaced, and masonry columns were strengthened with new brickwork

At the ground floor, there was one area where the joists were rotten and were replaced, and masonry columns were strengthened with new brickwork

At the ground floor, there was one area where the joists were rotten and were replaced, and masonry columns were strengthened with new brickwork

-

The eaves were stopped back to expose rafter ends and wall head joinery and several areas were replaced with new timber. Rafter roll ventilator tray was installed to provide a guaranteed ventilation route to the attic while ensuring the insulation is stuffed tightly into the corners

The eaves were stopped back to expose rafter ends and wall head joinery and several areas were replaced with new timber. Rafter roll ventilator tray was installed to provide a guaranteed ventilation route to the attic while ensuring the insulation is stuffed tightly into the corners

The eaves were stopped back to expose rafter ends and wall head joinery and several areas were replaced with new timber. Rafter roll ventilator tray was installed to provide a guaranteed ventilation route to the attic while ensuring the insulation is stuffed tightly into the corners

The eaves were stopped back to expose rafter ends and wall head joinery and several areas were replaced with new timber. Rafter roll ventilator tray was installed to provide a guaranteed ventilation route to the attic while ensuring the insulation is stuffed tightly into the corners

-

Over the preceding winter, many of the ceiling and wall plaster finishes had failed and in the end most were removed leaving only the bare bones of the building. This is a top floor flat with masonry repaired and all wall and ceiling finishes removed.

Over the preceding winter, many of the ceiling and wall plaster finishes had failed and in the end most were removed leaving only the bare bones of the building. This is a top floor flat with masonry repaired and all wall and ceiling finishes removed.

Over the preceding winter, many of the ceiling and wall plaster finishes had failed and in the end most were removed leaving only the bare bones of the building. This is a top floor flat with masonry repaired and all wall and ceiling finishes removed.

Over the preceding winter, many of the ceiling and wall plaster finishes had failed and in the end most were removed leaving only the bare bones of the building. This is a top floor flat with masonry repaired and all wall and ceiling finishes removed.

https://mail.passivehouseplus.co.uk/magazine/feature/flat-earth#sigProIdb90314ed7e

It was felt that even though the building is not in a conservation area, external insulation to the stone facade would not be appropriate, so an internal wall insulation solution was designed. Internal wall insulation is tricky though because it can cause increased risks associated with moisture, but we were also keen to trial the technique we had seen abroad where the insulation is installed directly against the masonry, relying not on air movement, but on the vapour permeability and hygroscopicity of the insulation to manage the moisture risk. Great care was taken and the whole element tested using WUFI hygrothermal calculations.

The WUFI calculations carried out by Greengauge demonstrated that all elements were safe, except the timbers in the internally- insulated wall facing the street and so it was decided to remove these. Removing joists increased costs but ensured that no future decay could come back to haunt the client. It also simplified the forming of the airtightness layer. Instead of being buried in the wall, a new perimeter beam was installed with insulation behind which also ensured that the otherwise tricky floor-to-wall detail was wholly thermal bridge-free.

One of the aspects of the push towards energy efficient retrofit that concerns us as a practice is that both planning / conservation and cost pressures are driving many towards, in some cases, poorly conceived internal insulation solutions. We worry about the long term effects this will have on moisture and maintenance of these retrofitted buildings, as well as the possible knock-on effects on occupant health.

The whole face of the building on the street side was re-pointed in lime, and damaged stone was replaced with matching sandstone components and some Lithomex lime-based repair mortars. This was in part a conservation effort, but also ensures that the inside of the insulated walls are kept as dry as possible by ensuring that the outer face of the wall was in tip top condition.

North elevation: stone work was in a poor state of repair. All cement pointing raked out, and stones marked up for indents or Lithomex repair

It was originally proposed to retain the existing gas boilers, but the funders were keen to see a demonstration of renewable technologies. However, it was not possible to agree with the planning department a fully renewable solution, so a compromise was reached where air source heat pumps (ASHPs) were located on the adjacent ground. These heat pumps supply heat to the four lower flats, while gas boilers supply the upper flats.

In addition to recovering heat from the outgoing air, we also specified wastewater heat recovery (WWHR) technology to recover heat from the outgoing hot water.

Example of a Lithomex repair to one of the curved bay cill stones, new indented lintel stone below

With low space heating demand, the hot water would become the largest component of any future heating bills, and WWHR systems help to mitigate this risk.

The rooms themselves were re-configured to improve layout and meet modern space standards. Old wiring was entirely stripped out and large areas of poor plaster finishes were replaced. A number of structural repairs were made, and decayed timber was repaired.

While a conventional chemical company quoted around £20,000 to spray the timbers of the building with chemical fungicides and biocides, JGA opted instead to engage a building pathologist to advise. With John Durie from Heritage & Design Ltd, suitable specifications were agreed which meant none of those chemicals were needed while ensuring the long term durability of the timber, and the health of the occupants.

A number of measures were introduced to support the building, occupants and client in adapting to the incoming demands of climate change. Care was taken to reduce the risk of overheating to zero per cent in PHPP through minor tweaks in glazing and opening sizes, although the relatively small south-facing windows meant the risk was already low, while additional measures were introduced to protect the building in the long term from increased rainfall.

Process

From a design perspective, by far the biggest issues were encountered in achieving planning permission. This took over a year and involved a great deal of dialogue and compromise. By contrast the building control process was very simple.

Contractors CCG were engaged from the outset and provided cost feedback and practical input. There was no tender process, but costs were independently assessed by a quantity surveyor. Works commenced in the Spring of 2021 with the intention of completing by the time of COP26 in November of that year. In the event, construction was finished in the autumn of 2022.

Large areas of internal finishes needed to be replaced which prolonged the early process, but otherwise works progressed without undue hiccups. The only major issue was that, ultimately, the necessary airtightness level was not achieved meaning that the project could not be certified as an Enerphit. The project taught us an important lesson as architects going forward: agree in advance with clients that we can insist contractually on the process employed by contractors to deliver airtightness. If the whole building is to be tested, the airtightness layer across the whole building should be accessible at the same time. This process is necessary to enable simple assessment, and to ensure that the project is at the required level of airtightness before internal finishes start to get in the way.

This article was originally published in issue 49 of Passive House Plus magazine. Want immediate access to all back issues and exclusive extra content? Click here to subscribe for as little as €15, or click here to receive the next issue free of charge

Inputting the actual airtightness results into PHPP gave us a final figure of 25.9 kWh/m2/a which shows how agonisingly close we came given the almost tenfold reduction from pre-retrofit performance, but it was irrelevant as the airtightness result itself was a standalone requirement of Enerphit.

After the lengths we had gone to as architects it also caused some reflection on the merits of a pass / fail threshold over a more graduated system, as this ‘all or nothing’ approach may represent an unacceptable risk to development managers.

Monitoring and analysis of Niddrie Road being undertaken by Prof. Tim Sharpe and Dr Alejandro Moreno-Rangel at Strathclyde University is ongoing. Although it is too soon to give definitive figures, early indications are that in most cases, the annual space heating usage is aligned with the 25 kWh/ m2/yr threshold for Enerphit, although usage is higher in two cases.

-

Sheep wool stuffed tightly between new windows and the masonry on the rear of the building in advance of external wall insulation (EWI) installation

Sheep wool stuffed tightly between new windows and the masonry on the rear of the building in advance of external wall insulation (EWI) installation

Sheep wool stuffed tightly between new windows and the masonry on the rear of the building in advance of external wall insulation (EWI) installation

Sheep wool stuffed tightly between new windows and the masonry on the rear of the building in advance of external wall insulation (EWI) installation

-

Heat pump and other pipework penetrations and the EWI starter rail on the rear wall

Heat pump and other pipework penetrations and the EWI starter rail on the rear wall

Heat pump and other pipework penetrations and the EWI starter rail on the rear wall

Heat pump and other pipework penetrations and the EWI starter rail on the rear wall

-

Extended rods installed into the rear masonry to support downpipes and services ducts installed within the insulation to protect and remove the myriad of telecoms cables from the face of the rear elevation

Extended rods installed into the rear masonry to support downpipes and services ducts installed within the insulation to protect and remove the myriad of telecoms cables from the face of the rear elevation

Extended rods installed into the rear masonry to support downpipes and services ducts installed within the insulation to protect and remove the myriad of telecoms cables from the face of the rear elevation

Extended rods installed into the rear masonry to support downpipes and services ducts installed within the insulation to protect and remove the myriad of telecoms cables from the face of the rear elevation

-

200mm mineral wool EWI boards being installed along with the over-cills required by planning to represent the covered stone cills

200mm mineral wool EWI boards being installed along with the over-cills required by planning to represent the covered stone cills

200mm mineral wool EWI boards being installed along with the over-cills required by planning to represent the covered stone cills

200mm mineral wool EWI boards being installed along with the over-cills required by planning to represent the covered stone cills

-

The finished rear façade

The finished rear façade

The finished rear façade

The finished rear façade

https://mail.passivehouseplus.co.uk/magazine/feature/flat-earth#sigProId07263fdf30

In all cases temperature, relative humidity and CO2 measurements remained within desired ranges and the properties did not appear to be adversely affected by one particularly warm period. The dwellings remained below 1,000 ppm CO2 for the whole period of monitoring thus far and there was no evidence of ventilation systems being turned off or disconnected. Ongoing measurements of interstitial condensation risk have indicated no concerns. Occupant feedback has been positive in relation to comfort and air quality, but with some concerns raised about equipment issues, particularly the heat pumps, a couple of which had early teething problems.

In addition a project-wide review was undertaken by CaCHE and others which returned a broadly positive review while acknowledging some of the challenges which had been faced.

-

The external walls were coated internally with a lime parge coat for airtightness and to prevent thermal bypass, with a plaster ceiling airtightness layer

The external walls were coated internally with a lime parge coat for airtightness and to prevent thermal bypass, with a plaster ceiling airtightness layer

The external walls were coated internally with a lime parge coat for airtightness and to prevent thermal bypass, with a plaster ceiling airtightness layer

The external walls were coated internally with a lime parge coat for airtightness and to prevent thermal bypass, with a plaster ceiling airtightness layer

-

The 450mm insulation in the loft had to be built up from the edges working inwards to maintain a working area

The 450mm insulation in the loft had to be built up from the edges working inwards to maintain a working area

The 450mm insulation in the loft had to be built up from the edges working inwards to maintain a working area

The 450mm insulation in the loft had to be built up from the edges working inwards to maintain a working area

-

The rear walls were lime-coated for airtightness but then boxed out for simple plaster boarding internally, with all insulation on the outside

The rear walls were lime-coated for airtightness but then boxed out for simple plaster boarding internally, with all insulation on the outside

The rear walls were lime-coated for airtightness but then boxed out for simple plaster boarding internally, with all insulation on the outside

The rear walls were lime-coated for airtightness but then boxed out for simple plaster boarding internally, with all insulation on the outside

-

Recoup waste water heat recovery units were installed below all baths and showers.

Recoup waste water heat recovery units were installed below all baths and showers.

Recoup waste water heat recovery units were installed below all baths and showers.

Recoup waste water heat recovery units were installed below all baths and showers.

-

Looking from the flat below, the bay window floor joinery was then built back up with a continuous airtight and insulation layer. Note the lack of joists in the bay windows, which were removed following WUFI investigations

Looking from the flat below, the bay window floor joinery was then built back up with a continuous airtight and insulation layer. Note the lack of joists in the bay windows, which were removed following WUFI investigations

Looking from the flat below, the bay window floor joinery was then built back up with a continuous airtight and insulation layer. Note the lack of joists in the bay windows, which were removed following WUFI investigations

Looking from the flat below, the bay window floor joinery was then built back up with a continuous airtight and insulation layer. Note the lack of joists in the bay windows, which were removed following WUFI investigations

-

Woodfibre insulation was then installed onto the lime plastered wall on all north walls and lime plaster coated, and the floor built back into the bay

Woodfibre insulation was then installed onto the lime plastered wall on all north walls and lime plaster coated, and the floor built back into the bay

Woodfibre insulation was then installed onto the lime plastered wall on all north walls and lime plaster coated, and the floor built back into the bay

Woodfibre insulation was then installed onto the lime plastered wall on all north walls and lime plaster coated, and the floor built back into the bay

https://mail.passivehouseplus.co.uk/magazine/feature/flat-earth#sigProId85327eda14

Interestingly a mainstream cost benefit analysis (CBA) was also undertaken which took a 30-year view and included an assessment of carbon. This analysis assessed the Enerphit approach against two counterfactuals and ran several sensitivity analyses against different assumptions, including a standard retrofit and a demolish and re-build alternative. It showed that the retrofit options were always better than the new-build option, while the long-term performance of the two retrofit approaches was comparable in purely cost terms.

However, it was noted that only the Enerphit approach got close to a net zero future, and that the comparability of the costs depended on whose money was being counted. In the standard retrofit, money was saved through a lower capital cost, but it was balanced in the long term by higher fuel bills.

This saved money for whoever funded the build but meant the occupants – all on social rent (and potentially housing benefit) were paying much more. Conversely, the savings made in the Enerphit model were all by those who have arguably most need. In the conversation about a just transition, the case for low energy buildings remains strong.

-

A great deal of snagging was done and photos of problem areas overlaid to clarify issues discovered

A great deal of snagging was done and photos of problem areas overlaid to clarify issues discovered

A great deal of snagging was done and photos of problem areas overlaid to clarify issues discovered

A great deal of snagging was done and photos of problem areas overlaid to clarify issues discovered

-

Project architect Drew Carr wondering why smoke was coming from a solid stone wall during a pressurisation test with smoke tracer.

Project architect Drew Carr wondering why smoke was coming from a solid stone wall during a pressurisation test with smoke tracer.

Project architect Drew Carr wondering why smoke was coming from a solid stone wall during a pressurisation test with smoke tracer.

Project architect Drew Carr wondering why smoke was coming from a solid stone wall during a pressurisation test with smoke tracer.

https://mail.passivehouseplus.co.uk/magazine/feature/flat-earth#sigProId8cb5b3bdfc

Occupant feedback

By Prof. Tim Sharpe and Dr Alejandro Moreno- Rangel, Department of Architecture, University of Strathclyde.

Occupants’ feedback on the indoor environment, energy use and overall satisfaction was collected on the first visit to each flat. Occupants reported overall satisfaction with all the aspects of the home, particularly the low energy bills.

Several of the occupants reported not having to pay for electricity during the period of the energy rebate from the government between October 2022 and March 2023. From a fuel poverty and affordability perspective, this was very positive for occupants as this suggests that the monthly energy bills were below £66 even with particularly high energy prices, and that some of this credit may have even rolled out to the further months. Some quotations from the interviews are:

“I wish all the homes were like this one. I have been very happy since I moved in and I don’t need to worry about the energy bills”

“The house was too warm during winter, but after a visit from the engineers to look out to my boiler everything was good. I haven’t had any problems since then. My house is comfortable and cheap to heat.”

Selected project details

Client: Southside Housing Association

Architect: John Gilbert Architects (JGA)

Civil / structural engineer: Design Engineering Works

Energy consultant: JGA + Passivhaus Associates

Project management: John Gilbert Architects (JGA)

Main contractor: CCG (Scotland)

Quantity surveyors: NBM Cost Consultants

Airtightness tester/consultant: JGA + Thermal Image UK

Passive house certifier: WARM

Wall insulation: EWI - K Systems

Thermal breaks: Foamglas

Airtightness products: Pro Clima, from Ecological Building Systems

Windows and doors: Green Building Store (now 21 Degrees)

Drainage / paving: Rainwater Goods - Alumasc

Heat pump: Mitsubishi Ecodan

Gas boilers: Vaillant

MVHR: Zehnder, via Paul Heat Recovery

Water conserving fittings: Recoup Waste Water Heat Recovery

Project overview

Holistic and ultra-low energy retrofit of a traditional Scottish sandstone tenement in Glasgow.

Building type: Sandstone built, four-storey tenement, built around 1900. Eight one-bedroom flats either side of central stair. Flats are around 47 m2 each. Traditionally built: solid sandstone walls, timber roof and floors with slate roof.

Site type & location: Urban site, Niddrie Road, Southside, Glasgow

Budget: Initial pre-start price was c. £700k which was c. £88k per flat, of which c. £36k per flat (43 per cent) was for energy upgrades, the rest for planned maintenance and repair works. Significant additional strip-out was required meaning the ultimate cost of the project was just over £1m. All of this additional cost related to repair and maintenance work except for the replacement of four gas boilers with ASHPs as required by funding bodies. Costs exclude building purchase (already owned) and fees

Completion date: Site start: July 2020

Completion: June 2022

Passive house certification: Not sought. Certifiers WARM were involved all the way through

Space heating demand: Before: 235 kWh/m2/yr (using SAP and as an average over several flats).

After: 25.9 kWh/m2/yr using PHPP and factoring in 1.65 air leakage

Heat load: Before: Not calculated.

After: 18.7 W/m2 using PhPP

Primary energy non-renewable (PHPP):

Before: Not calculated. After: 140 kWh/m2/yr

Primary energy renewable (PHPP):

Before: Not calculated. After: 87 kWh/m2/yr

Heat loss form factor: 2.08, using PHPP

Overheating: 0 per cent of year above 250C, using PHPP

Environmental assessment method: RdSAP / SAP PHPP

Embodied carbon: Not calculated

Energy performance certificate (EPC):

Before: Range from E54 - D57.

After: Range from B81 - B85

Monitored energy use:

Before: Not monitored - building was empty.

After: Monitoring – which does not include metres on heating appliances – is ongoing, so it is too soon to give definitive results. Thermal bridging: All significant thermal bridges were calculated in THERM by WARM as a separate contract to the certification process. Important adjustments made to otherwise standard detailing included at the eaves on both front and rear, as well as around the ground floor perimeter. We also carried out WUFI hygrothermal calculations which led us to adjust the mid-floor details as well, and this had knock-on benefits on the thermal bridging as well as avoiding moisture risk.

Airtightness (at 50 Pascals):

Before: Not tested.

After: 1.6 ACH

Ground floor:

Before: e.g. Uninsulated timber suspended floor: 1.9 W/m2K.

After: 325 mm mineral wool insulation between and below floor joists, airtightness membrane over original boards and breather membrane below. U-Value: 0.11 W/m2K

North (street facing) walls:

Before: Solid sandstone with mix of original lath and plaster or modern plasterboard internal lining over c.50 mm cavity. U-value: 1.4 W/m2K

After: External face of stone repaired / lime pointed. Internal linings removed, lime parge directly onto masonry (windtightness), 120 mm wood fibre boards and lime plaster skim (airtightness) with mineral paint decoration. U-value: 0.38 W/m2K

South + west (rear facing + gable) walls:

Before: Solid sandstone with mix of original lath and plaster or modern plasterboard internal lining over c.50 mm cavity. U-value: 1.5 W/m2K.

After: 200 mm mineral wool external insulation boards over masonry with silicone render. Lime parge coat internally for airtightness. U-value: 0.18 W/m2K

Roof:

Before: Open vented attic with uninsulated ceiling, lath and plaster ceiling. U-value: 1.9 W/m2K.

After: 490 mm mineral wool laid between joists and over with wind-tightness breather membrane over. Plaster ceiling skimmed for airtightness. U-value: 0.07 W/m2K

Windows & doors:

Before: Mix of single and double glazed PVCu windows. Overall approximate U-value: 3.00 W/m2K.

After: New triple glazed windows from Green Building Store (21 Degrees). PHI certified Ultra tilt + turn triple glazed insulated timber with 2x argon fill, 98 profile. FSC Certification, Secure by Design, Class 4 Airtightness. Overall whole window U-value of 0.68 W/m2K (to BS EN 14351)

Heating system 1:

Before: c. 15-yr old gas boilers + radiators.

After: Mitsubishi Ecodan FTC6 Packaged Cylinder with Ecodan R32 Monobloc External Unit. 200 litre storage. New radiators throughout

Heating system 2:

Before: c. 15-yr old gas boilers + radiators.

After: Valiant ecoTEC pro combi boilers. New radiators throughout

Ventilation:

Before: Openable windows. Some flats had intermittent extract fans in kitchens or bathrooms or both

After: Zehnder ComfoAir 160 installed in bathroom ceilings with semi-rigid ducting in hallway lowered ceilings to all rooms. PHI certified @ 89 per cent HR efficiency

Water: Recoup Easyfit+ wastewater heat recovery system. Installed in six upper flats but not two ground floor flats

Electricity: No renewable electricity generation or storage

Sustainable materials: Woodfibre used for internal insulation. Lime mortar used in preference to plastic membranes for airtightness. No chemicals used for timber treatment / certification provided by consultant rather than treatment company. Lime pointing, lithomex, stone repair and Keim mineral paint to external face of internally insulated walls. Triple glazing was timber frame. Internal paint was mineral based.

Image gallery

-

One of the first jobs was to cover the masonry external walls internally with a lime parge coat for airtightness and to prevent thermal bypass. Plaster was also used in the ceilings as the airtightness layer

One of the first jobs was to cover the masonry external walls internally with a lime parge coat for airtightness and to prevent thermal bypass. Plaster was also used in the ceilings as the airtightness layer

One of the first jobs was to cover the masonry external walls internally with a lime parge coat for airtightness and to prevent thermal bypass. Plaster was also used in the ceilings as the airtightness layer

One of the first jobs was to cover the masonry external walls internally with a lime parge coat for airtightness and to prevent thermal bypass. Plaster was also used in the ceilings as the airtightness layer

-

Foamglas thermal breaks formed in supporting walls to the re-built ground floor

Foamglas thermal breaks formed in supporting walls to the re-built ground floor

Foamglas thermal breaks formed in supporting walls to the re-built ground floor

Foamglas thermal breaks formed in supporting walls to the re-built ground floor

-

The 450mm insulation in the loft had to be built up from the edges working inwards to maintain a working area

The 450mm insulation in the loft had to be built up from the edges working inwards to maintain a working area

The 450mm insulation in the loft had to be built up from the edges working inwards to maintain a working area

The 450mm insulation in the loft had to be built up from the edges working inwards to maintain a working area

-

A breather membrane was installed over the loft insulation with all cables lifted above the insulation. This was work in progress with access run down the middle

A breather membrane was installed over the loft insulation with all cables lifted above the insulation. This was work in progress with access run down the middle

A breather membrane was installed over the loft insulation with all cables lifted above the insulation. This was work in progress with access run down the middle

A breather membrane was installed over the loft insulation with all cables lifted above the insulation. This was work in progress with access run down the middle

-

New partitions were formed to create more sensible layouts

New partitions were formed to create more sensible layouts

New partitions were formed to create more sensible layouts

New partitions were formed to create more sensible layouts

-

Beneath the ground floor, the walls were lime parge-coated and insulation boards installed ‘down’ the walls on the inside below the joists to reduce the thermal bridge to an acceptable level, as designed with THERM thermal bridging software

Beneath the ground floor, the walls were lime parge-coated and insulation boards installed ‘down’ the walls on the inside below the joists to reduce the thermal bridge to an acceptable level, as designed with THERM thermal bridging software

Beneath the ground floor, the walls were lime parge-coated and insulation boards installed ‘down’ the walls on the inside below the joists to reduce the thermal bridge to an acceptable level, as designed with THERM thermal bridging software

Beneath the ground floor, the walls were lime parge-coated and insulation boards installed ‘down’ the walls on the inside below the joists to reduce the thermal bridge to an acceptable level, as designed with THERM thermal bridging software

-

The rear walls were lime-coated for airtightness but then boxed out for simple plaster boarding internally, all the insulation was on the outside

The rear walls were lime-coated for airtightness but then boxed out for simple plaster boarding internally, all the insulation was on the outside

The rear walls were lime-coated for airtightness but then boxed out for simple plaster boarding internally, all the insulation was on the outside

The rear walls were lime-coated for airtightness but then boxed out for simple plaster boarding internally, all the insulation was on the outside

-

MVHR units were installed in the ceilings of the bathrooms and air ducted within a dropped ceiling through the hallways to all rooms

MVHR units were installed in the ceilings of the bathrooms and air ducted within a dropped ceiling through the hallways to all rooms

MVHR units were installed in the ceilings of the bathrooms and air ducted within a dropped ceiling through the hallways to all rooms

MVHR units were installed in the ceilings of the bathrooms and air ducted within a dropped ceiling through the hallways to all rooms

-

Recoup waste water heat recovery units were installed below all baths and showers

Recoup waste water heat recovery units were installed below all baths and showers

Recoup waste water heat recovery units were installed below all baths and showers

Recoup waste water heat recovery units were installed below all baths and showers

-

Heat pump internal units were installed in cupboards and connected to external units

Heat pump internal units were installed in cupboards and connected to external units

Heat pump internal units were installed in cupboards and connected to external units

Heat pump internal units were installed in cupboards and connected to external units

-

On four upper floor flats, gas boilers were installed

On four upper floor flats, gas boilers were installed

On four upper floor flats, gas boilers were installed

On four upper floor flats, gas boilers were installed

-

On the externally insulated rear wall, internal insulation was needed at the party walls to return and reduce the thermal bridge

On the externally insulated rear wall, internal insulation was needed at the party walls to return and reduce the thermal bridge

On the externally insulated rear wall, internal insulation was needed at the party walls to return and reduce the thermal bridge

On the externally insulated rear wall, internal insulation was needed at the party walls to return and reduce the thermal bridge

-

The floor of the close was excavated and insulation installed before a concrete slab was poured on top

The floor of the close was excavated and insulation installed before a concrete slab was poured on top

The floor of the close was excavated and insulation installed before a concrete slab was poured on top

The floor of the close was excavated and insulation installed before a concrete slab was poured on top

-

New, larger living spaces were formed facing the street with kitchen alcoves making for a far nicer layout

New, larger living spaces were formed facing the street with kitchen alcoves making for a far nicer layout

New, larger living spaces were formed facing the street with kitchen alcoves making for a far nicer layout

New, larger living spaces were formed facing the street with kitchen alcoves making for a far nicer layout

-

Space was very limited by the entrance door so Aerogel panels were used to close off the thermal bridging of the adjacent partition walls

Space was very limited by the entrance door so Aerogel panels were used to close off the thermal bridging of the adjacent partition walls

Space was very limited by the entrance door so Aerogel panels were used to close off the thermal bridging of the adjacent partition walls

Space was very limited by the entrance door so Aerogel panels were used to close off the thermal bridging of the adjacent partition walls

-

A rear living space with boiler cupboard and adjacent kitchen with initial strip of the external wall finishes

A rear living space with boiler cupboard and adjacent kitchen with initial strip of the external wall finishes

A rear living space with boiler cupboard and adjacent kitchen with initial strip of the external wall finishes

A rear living space with boiler cupboard and adjacent kitchen with initial strip of the external wall finishes

-

The toilets were preposterously narrow and it was agreed that these needed to be changed

The toilets were preposterously narrow and it was agreed that these needed to be changed

The toilets were preposterously narrow and it was agreed that these needed to be changed

The toilets were preposterously narrow and it was agreed that these needed to be changed

-

Some of the supporting masonry structure was far from robust or stable, so quite a lot of urgent structural improvements were made early on

Some of the supporting masonry structure was far from robust or stable, so quite a lot of urgent structural improvements were made early on

Some of the supporting masonry structure was far from robust or stable, so quite a lot of urgent structural improvements were made early on

Some of the supporting masonry structure was far from robust or stable, so quite a lot of urgent structural improvements were made early on

-

27 It became clear that not one of the internal partition walls were tied into the front and rear stone walls, so ties were hastily installed. 1m returns were also stripped back to reduce the thermal bridge at all partition walls, and in this photo the holes where the timber ‘doors’ had been were filled

27 It became clear that not one of the internal partition walls were tied into the front and rear stone walls, so ties were hastily installed. 1m returns were also stripped back to reduce the thermal bridge at all partition walls, and in this photo the holes where the timber ‘doors’ had been were filled

27 It became clear that not one of the internal partition walls were tied into the front and rear stone walls, so ties were hastily installed. 1m returns were also stripped back to reduce the thermal bridge at all partition walls, and in this photo the holes where the timber ‘doors’ had been were filled

27 It became clear that not one of the internal partition walls were tied into the front and rear stone walls, so ties were hastily installed. 1m returns were also stripped back to reduce the thermal bridge at all partition walls, and in this photo the holes where the timber ‘doors’ had been were filled

-

28 At the ground floor, there was one area where the joists were rotten and were replaced, and masonry columns were strengthened with new brickwork

28 At the ground floor, there was one area where the joists were rotten and were replaced, and masonry columns were strengthened with new brickwork

28 At the ground floor, there was one area where the joists were rotten and were replaced, and masonry columns were strengthened with new brickwork

28 At the ground floor, there was one area where the joists were rotten and were replaced, and masonry columns were strengthened with new brickwork

-

Stone mullions could be removed from the rear windows because it turned out the lintels went all the way across anyway

Stone mullions could be removed from the rear windows because it turned out the lintels went all the way across anyway

Stone mullions could be removed from the rear windows because it turned out the lintels went all the way across anyway

Stone mullions could be removed from the rear windows because it turned out the lintels went all the way across anyway

-

Along the front wall, we removed all timber joints, took the lime page coat completely over to simplify the airtightness at this critical junction, then installed Foamglas pads against which to install a ‘perimeter beam'

Along the front wall, we removed all timber joints, took the lime page coat completely over to simplify the airtightness at this critical junction, then installed Foamglas pads against which to install a ‘perimeter beam'

Along the front wall, we removed all timber joints, took the lime page coat completely over to simplify the airtightness at this critical junction, then installed Foamglas pads against which to install a ‘perimeter beam'

Along the front wall, we removed all timber joints, took the lime page coat completely over to simplify the airtightness at this critical junction, then installed Foamglas pads against which to install a ‘perimeter beam'

-

A large cast iron downpipe had been installed within one of the central brick partition walls. This was removed and the wall stitched back together

A large cast iron downpipe had been installed within one of the central brick partition walls. This was removed and the wall stitched back together

A large cast iron downpipe had been installed within one of the central brick partition walls. This was removed and the wall stitched back together

A large cast iron downpipe had been installed within one of the central brick partition walls. This was removed and the wall stitched back together

-

The eaves were stopped back to expose rafter ends and wall head joinery and several areas were replaced with new timber

The eaves were stopped back to expose rafter ends and wall head joinery and several areas were replaced with new timber

The eaves were stopped back to expose rafter ends and wall head joinery and several areas were replaced with new timber

The eaves were stopped back to expose rafter ends and wall head joinery and several areas were replaced with new timber

-

Rafter roll ventilator tray was installed to provide a guaranteed ventilation route to the attic while ensuring the insulation is stuffed tightly into the corners

Rafter roll ventilator tray was installed to provide a guaranteed ventilation route to the attic while ensuring the insulation is stuffed tightly into the corners

Rafter roll ventilator tray was installed to provide a guaranteed ventilation route to the attic while ensuring the insulation is stuffed tightly into the corners

Rafter roll ventilator tray was installed to provide a guaranteed ventilation route to the attic while ensuring the insulation is stuffed tightly into the corners

-

Looking from one flat upwards to another flat above. After WUFI investigations into the safety of the timber joists in the front walls, the decision was taken to remove the joists in the bay windows. Some of the masonry to be lime plastered was in a very poor condition and this involved a fair bit of remedial works before a lime parge coat could be applied

Looking from one flat upwards to another flat above. After WUFI investigations into the safety of the timber joists in the front walls, the decision was taken to remove the joists in the bay windows. Some of the masonry to be lime plastered was in a very poor condition and this involved a fair bit of remedial works before a lime parge coat could be applied

Looking from one flat upwards to another flat above. After WUFI investigations into the safety of the timber joists in the front walls, the decision was taken to remove the joists in the bay windows. Some of the masonry to be lime plastered was in a very poor condition and this involved a fair bit of remedial works before a lime parge coat could be applied

Looking from one flat upwards to another flat above. After WUFI investigations into the safety of the timber joists in the front walls, the decision was taken to remove the joists in the bay windows. Some of the masonry to be lime plastered was in a very poor condition and this involved a fair bit of remedial works before a lime parge coat could be applied

-

Over the preceding winter, many of the ceiling and wall plaster finishes had failed and in the end most were removed leaving only the bare bones of the building. This is a top floor flat with masonry repaired and all wall and ceiling finishes removed

Over the preceding winter, many of the ceiling and wall plaster finishes had failed and in the end most were removed leaving only the bare bones of the building. This is a top floor flat with masonry repaired and all wall and ceiling finishes removed

Over the preceding winter, many of the ceiling and wall plaster finishes had failed and in the end most were removed leaving only the bare bones of the building. This is a top floor flat with masonry repaired and all wall and ceiling finishes removed

Over the preceding winter, many of the ceiling and wall plaster finishes had failed and in the end most were removed leaving only the bare bones of the building. This is a top floor flat with masonry repaired and all wall and ceiling finishes removed

-

As usual the attic had a huge amount of debris and some inadequate existing insulation. This was all removed and a new plasterboard ceiling fitted below. This was the loft before new insulation install began.

As usual the attic had a huge amount of debris and some inadequate existing insulation. This was all removed and a new plasterboard ceiling fitted below. This was the loft before new insulation install began.

As usual the attic had a huge amount of debris and some inadequate existing insulation. This was all removed and a new plasterboard ceiling fitted below. This was the loft before new insulation install began.

As usual the attic had a huge amount of debris and some inadequate existing insulation. This was all removed and a new plasterboard ceiling fitted below. This was the loft before new insulation install began.

-

We engaged John Durie of Heritage and Design to help agree a specification to ensure that the risk of damp and timber rot was removed, without the need for any chemical treatments.

We engaged John Durie of Heritage and Design to help agree a specification to ensure that the risk of damp and timber rot was removed, without the need for any chemical treatments.

We engaged John Durie of Heritage and Design to help agree a specification to ensure that the risk of damp and timber rot was removed, without the need for any chemical treatments.

We engaged John Durie of Heritage and Design to help agree a specification to ensure that the risk of damp and timber rot was removed, without the need for any chemical treatments.

-

With strip out finally complete and everything tidied away the flats were momentarily spacious and tidy

With strip out finally complete and everything tidied away the flats were momentarily spacious and tidy

With strip out finally complete and everything tidied away the flats were momentarily spacious and tidy

With strip out finally complete and everything tidied away the flats were momentarily spacious and tidy

-

North elevation: stone work was in a poor state of repair. All cement pointing raked out, and stones marked up for indents or Lithomex repair

North elevation: stone work was in a poor state of repair. All cement pointing raked out, and stones marked up for indents or Lithomex repair

North elevation: stone work was in a poor state of repair. All cement pointing raked out, and stones marked up for indents or Lithomex repair

North elevation: stone work was in a poor state of repair. All cement pointing raked out, and stones marked up for indents or Lithomex repair

-

Sample repointing panel agreed on site with different mortar mix and finish to match existing

Sample repointing panel agreed on site with different mortar mix and finish to match existing

Sample repointing panel agreed on site with different mortar mix and finish to match existing

Sample repointing panel agreed on site with different mortar mix and finish to match existing

-

Looking from the flat below, the bay window floor joinery was then built back up with a continuous airtight layer and a continuous insulation layer. Note the lack of joists in the bay windows. (Following WUFI investigations during the strip out stage on the safety of the timber joists in the front walls, the decision had been taken taken to remove bay window joists).

Looking from the flat below, the bay window floor joinery was then built back up with a continuous airtight layer and a continuous insulation layer. Note the lack of joists in the bay windows. (Following WUFI investigations during the strip out stage on the safety of the timber joists in the front walls, the decision had been taken taken to remove bay window joists).

Looking from the flat below, the bay window floor joinery was then built back up with a continuous airtight layer and a continuous insulation layer. Note the lack of joists in the bay windows. (Following WUFI investigations during the strip out stage on the safety of the timber joists in the front walls, the decision had been taken taken to remove bay window joists).

Looking from the flat below, the bay window floor joinery was then built back up with a continuous airtight layer and a continuous insulation layer. Note the lack of joists in the bay windows. (Following WUFI investigations during the strip out stage on the safety of the timber joists in the front walls, the decision had been taken taken to remove bay window joists).

-

Completed works on the right with new stone indents and adjacent building to the left of the downpipe

Completed works on the right with new stone indents and adjacent building to the left of the downpipe

Completed works on the right with new stone indents and adjacent building to the left of the downpipe

Completed works on the right with new stone indents and adjacent building to the left of the downpipe

-

Example of a Lithomex repair to one of the curved bay cill stones, new indented lintel stone below

Example of a Lithomex repair to one of the curved bay cill stones, new indented lintel stone below

Example of a Lithomex repair to one of the curved bay cill stones, new indented lintel stone below

Example of a Lithomex repair to one of the curved bay cill stones, new indented lintel stone below

-

Depth of gable insulation partially obscured by a downpipe moved to the corner

Depth of gable insulation partially obscured by a downpipe moved to the corner

Depth of gable insulation partially obscured by a downpipe moved to the corner

Depth of gable insulation partially obscured by a downpipe moved to the corner

-

Forming new insulated bay roofs, with refreshed lead finish and lead flashing below the gutter to protect the stonework in the event of gutter overflow

Forming new insulated bay roofs, with refreshed lead finish and lead flashing below the gutter to protect the stonework in the event of gutter overflow

Forming new insulated bay roofs, with refreshed lead finish and lead flashing below the gutter to protect the stonework in the event of gutter overflow

Forming new insulated bay roofs, with refreshed lead finish and lead flashing below the gutter to protect the stonework in the event of gutter overflow

-

Finished roof work on the bay windows with enlarged gutter

Finished roof work on the bay windows with enlarged gutter

Finished roof work on the bay windows with enlarged gutter

Finished roof work on the bay windows with enlarged gutter

-

Sheep wool stuffed tightly between new windows and the masonry on the rear of the building in advance of external wall insulation (EWI) installation

Sheep wool stuffed tightly between new windows and the masonry on the rear of the building in advance of external wall insulation (EWI) installation

Sheep wool stuffed tightly between new windows and the masonry on the rear of the building in advance of external wall insulation (EWI) installation

Sheep wool stuffed tightly between new windows and the masonry on the rear of the building in advance of external wall insulation (EWI) installation

-

Heat pump and other pipework penetrations and the EWI starter rail on the rear wall

Heat pump and other pipework penetrations and the EWI starter rail on the rear wall

Heat pump and other pipework penetrations and the EWI starter rail on the rear wall

Heat pump and other pipework penetrations and the EWI starter rail on the rear wall

-

Extended rods installed into the rear masonry to support downpipes and services ducts installed within the insulation to protect and remove the myriad of telecoms cables from the face of the rear elevation

Extended rods installed into the rear masonry to support downpipes and services ducts installed within the insulation to protect and remove the myriad of telecoms cables from the face of the rear elevation

Extended rods installed into the rear masonry to support downpipes and services ducts installed within the insulation to protect and remove the myriad of telecoms cables from the face of the rear elevation

Extended rods installed into the rear masonry to support downpipes and services ducts installed within the insulation to protect and remove the myriad of telecoms cables from the face of the rear elevation

-

200mm mineral wool EWI boards being installed along with the over-cills required by planning to represent the covered stone cills

200mm mineral wool EWI boards being installed along with the over-cills required by planning to represent the covered stone cills

200mm mineral wool EWI boards being installed along with the over-cills required by planning to represent the covered stone cills

200mm mineral wool EWI boards being installed along with the over-cills required by planning to represent the covered stone cills

-

Completed EWI with heat pump external units in place but various external works and services connections to be completed

Completed EWI with heat pump external units in place but various external works and services connections to be completed

Completed EWI with heat pump external units in place but various external works and services connections to be completed

Completed EWI with heat pump external units in place but various external works and services connections to be completed

-

5 Woodfibre insulation was then installed onto the lime plastered wall on all north walls and lime plaster coated, and the floor built back into the bay. This also shows the new windows installed and insulated

5 Woodfibre insulation was then installed onto the lime plastered wall on all north walls and lime plaster coated, and the floor built back into the bay. This also shows the new windows installed and insulated

5 Woodfibre insulation was then installed onto the lime plastered wall on all north walls and lime plaster coated, and the floor built back into the bay. This also shows the new windows installed and insulated

5 Woodfibre insulation was then installed onto the lime plastered wall on all north walls and lime plaster coated, and the floor built back into the bay. This also shows the new windows installed and insulated

-

The insulation in the loft didn’t meet the external wall insulation so we had to build a joining section which then had to be finished in its own ventilated lead roof

The insulation in the loft didn’t meet the external wall insulation so we had to build a joining section which then had to be finished in its own ventilated lead roof

The insulation in the loft didn’t meet the external wall insulation so we had to build a joining section which then had to be finished in its own ventilated lead roof

The insulation in the loft didn’t meet the external wall insulation so we had to build a joining section which then had to be finished in its own ventilated lead roof

-

A great deal of snagging was done and photos of problem areas overlaid to clarify issues discovered

A great deal of snagging was done and photos of problem areas overlaid to clarify issues discovered

A great deal of snagging was done and photos of problem areas overlaid to clarify issues discovered

A great deal of snagging was done and photos of problem areas overlaid to clarify issues discovered

-

A Matterport model of the whole building was made and updated over a series of visits to create an interactive model of the changing state of the building through the process

A Matterport model of the whole building was made and updated over a series of visits to create an interactive model of the changing state of the building through the process

A Matterport model of the whole building was made and updated over a series of visits to create an interactive model of the changing state of the building through the process

A Matterport model of the whole building was made and updated over a series of visits to create an interactive model of the changing state of the building through the process

-

Project architect Drew Carr wondering why smoke was coming from a solid stone wall during a pressurisation test with smoke tracer

Project architect Drew Carr wondering why smoke was coming from a solid stone wall during a pressurisation test with smoke tracer

Project architect Drew Carr wondering why smoke was coming from a solid stone wall during a pressurisation test with smoke tracer

Project architect Drew Carr wondering why smoke was coming from a solid stone wall during a pressurisation test with smoke tracer

-

Several airtightness tests were undertaken to get the building over the line with airtightness, but the Enerphit target of 1.0 ACH was not to be

Several airtightness tests were undertaken to get the building over the line with airtightness, but the Enerphit target of 1.0 ACH was not to be

Several airtightness tests were undertaken to get the building over the line with airtightness, but the Enerphit target of 1.0 ACH was not to be

Several airtightness tests were undertaken to get the building over the line with airtightness, but the Enerphit target of 1.0 ACH was not to be

-

A variety of sensors were installed to provide ongoing monitoring of the building, including these moisture content sensors from Omnisense installed into timber joists

A variety of sensors were installed to provide ongoing monitoring of the building, including these moisture content sensors from Omnisense installed into timber joists

A variety of sensors were installed to provide ongoing monitoring of the building, including these moisture content sensors from Omnisense installed into timber joists

A variety of sensors were installed to provide ongoing monitoring of the building, including these moisture content sensors from Omnisense installed into timber joists

-

Woodfibre insulation installed and ceilings going back in to one of the north-facing bays

Woodfibre insulation installed and ceilings going back in to one of the north-facing bays

Woodfibre insulation installed and ceilings going back in to one of the north-facing bays

Woodfibre insulation installed and ceilings going back in to one of the north-facing bays

-

One of the north bays plastered with new windows and surrounding joinery, just needing painted

One of the north bays plastered with new windows and surrounding joinery, just needing painted

One of the north bays plastered with new windows and surrounding joinery, just needing painted

One of the north bays plastered with new windows and surrounding joinery, just needing painted

-

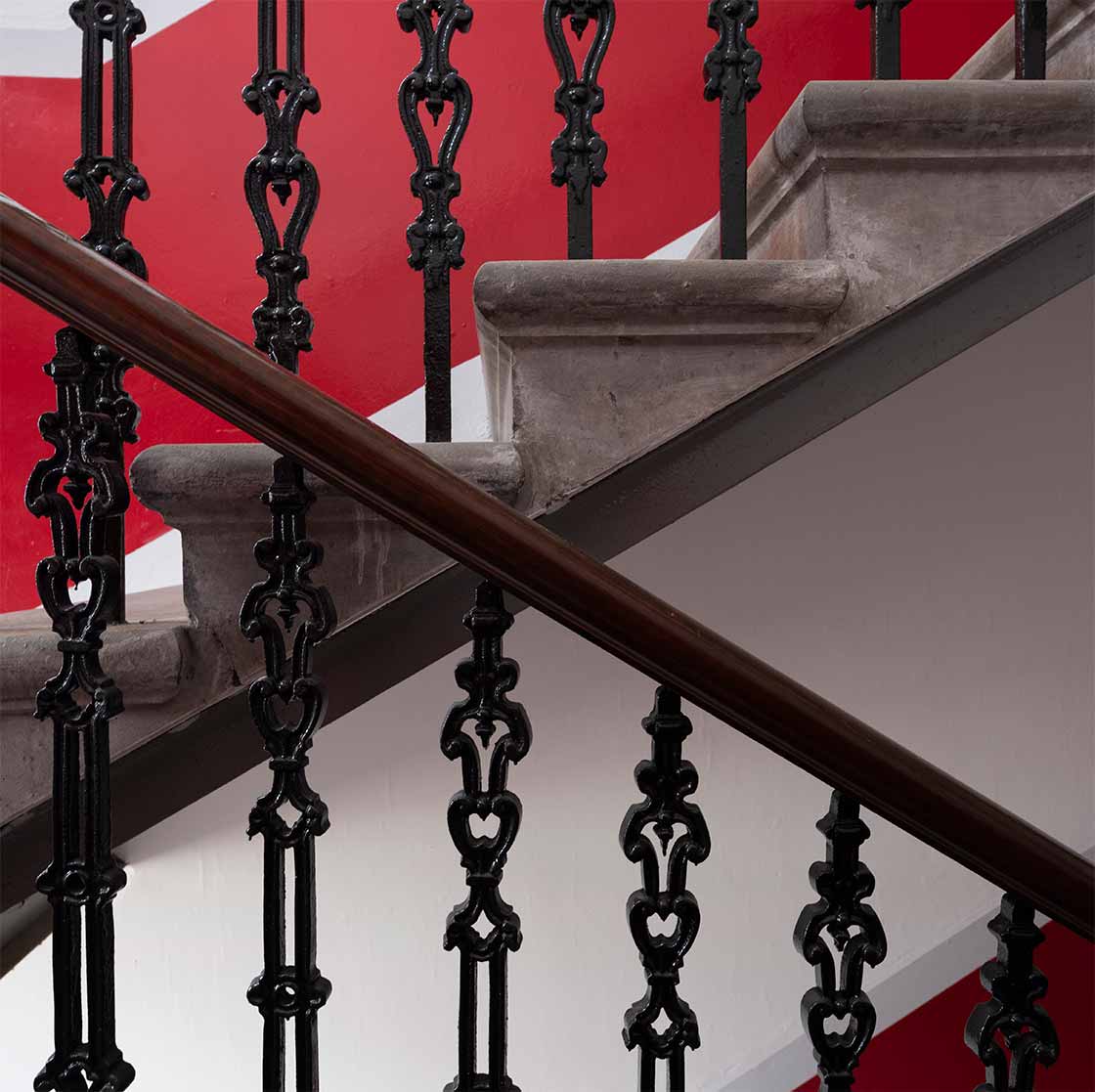

The North facing stairwell had to be insulated too, with thinner returns on both stairwell walls

The North facing stairwell had to be insulated too, with thinner returns on both stairwell walls

The North facing stairwell had to be insulated too, with thinner returns on both stairwell walls

The North facing stairwell had to be insulated too, with thinner returns on both stairwell walls

-

With stairwell insulation completed and undergoing redecoration

With stairwell insulation completed and undergoing redecoration

With stairwell insulation completed and undergoing redecoration

With stairwell insulation completed and undergoing redecoration

https://mail.passivehouseplus.co.uk/magazine/feature/flat-earth#sigProIdfc1337c78a