- Feature

- Posted

Material matters - A palette for a vulnerable planet

In recent years, the drive to reduce the embodied carbon of buildings has led to a resurgent interest in timber and other biobased building materials. But peering into the future, if we are to think not just about carbon but also land, water, and regenerating nature, how might we build to meet our essential needs, and what might we build with?

By Lenny Antonelli and Andy Simmonds

This article was originally published in issue 49 of Passive House Plus magazine. Want immediate access to all back issues and exclusive extra content? Click here to subscribe for as little as €15, or click here to receive the next issue free of charge

It’s something of an occupational hazard: architects typically prefer to talk about the loveliness of materials rather than the maths of building physics or operational energy. As a result, it is little surprise that, as embodied carbon has moved up the green building agenda and spurred on by TED Talks and articles in major newspapers, mass timber in particular has become more popular as a lower carbon alternative to concrete and steel.

Three years ago, here in Passive House Plus, we wrote that this resurgent enthusiasm for timber had things backward – rather than think first about what materials to specify, we should prioritise building nothing or building less, retrofitting more, and using materials and built space more efficiently. No material palette can sustainably meet our needs in economies chasing endless growth.

We worried about simplistic assumptions which implied that every new wooden building helped to cool the planet. And about whether – in scenarios where we built far more with wood – forests could provide for our timber needs while still protecting and restoring biodiversity.

Recent research has emphasised the limits of forests to provide wood products, and the limits of wood products to mitigate climate warming. In 2021, engineers from the University of Bath warned that “all construction is likely to warm the planet”, including timber construction. In 2021, Swedish scientists argued that reducing wood harvests would provide “large and rapid mitigation” of carbon emissions by increasing forest carbon sinks”.

In their paper ‘Land use change and carbon emissions of a transformation to timber cities’, scientists from the Potsdam Institute for Climate Research found that housing 90 per cent of the world’s new urban population in timber buildings up to 2100 would save 106 gigatonnes of CO2 compared to a business as usual scenario – but this would require an additional 149 million hectares of new forest plantations, and likely lead to some loss of biodiversity.

Other research shows specific, long-term climate benefits for a carefully regulated increase in the use of wood products. ‘Can temperate forests deliver future wood demand and climate mitigation?’, a paper published by researchers at the University of Bangor says there is “considerable but constrained potential” for an increase in wood use to mitigate climate warming, but that limiting demand for wood, managing forests sustainably and using (and reusing) wood efficiently are all critical to achieving this.

The science of how we account for the climate impact of different forest management systems is still evolving, and we should not treat timber as a panacea. We wonder if – once we have minimised the need for new construction and new materials – a more sensible approach would be to ask what materials local techno-systems and ecosystems can provide while sequestering carbon, supporting local livelihoods, regenerating nature and protecting water quality.

Beyond just timber

Salvaged steel used at Grosvenor’s Holbein Gardens in London. Photo: Heyne Tillett Steel

The vast majority of buildings in the developed world rely on a very limited range of materials. Structural elements are usually of concrete, steel or wood. Insulation tends to be plastic, mineral, wood or natural fibre based, while claddings and linings draw on a slightly larger palette. Undoubtedly, globalised capital prefers to sell a small number of fairly uniform products.

But it wasn’t always like this.

Up until the mid-20th century, global material flows were extracted overwhelmingly from earth, or mineral-based quarried or mined materials and renewable, biological sources such as forests and agricultural processes. The “vast majority of building materials were locally sourced,” says a major recent report, 'Building Materials and the Climate', written for the United Nations Environment Programme by leading architects at Yale University. “It has only been in the last several decades that the majority of building materials come from extractive, toxic, non-renewable processes”.

So, how might we now re-diversify our material palette not just to minimise carbon emissions, but to reduce and reuse waste and regenerate nature?

To help guide our thinking, we spoke with Dr Will Hawkins at the University of Bath, a structural engineer and an expert in decarbonising building materials, and his PhD student, Charlotte Taylor, whose research project is titled, ‘Ecologically constrained building design: what can we build from the zero-carbon resource pool?’.

For us, this title frames the question in a suitably radical way: not, what materials can satisfy our demand for growth, but what materials are compatible with a realistic view of delivering zero emissions by 2050, and if we only use these materials, how should we prioritise building?

Taylor suggests that we think about materials in a hierarchy, with those reused from the ‘technosphere’ near the top. Developing this hierarchy further, next comes biobased co-products, products of agriculture and forestry, followed by fast-growing crops grown on minimal land, in rotation with other crops, or in mixed farming systems. Local and minimally processed mineral and earth-based materials, and sustainable timber, might be somewhere around the middle of the hierarchy. Heavy, polluting materials like cement and steel are at the bottom.

We present this framework not as a sure thing, but as an initial proposal for discussion.

Materials from the old technosphere

Ideally, old buildings would always be our first port of call when we need ‘new’ materials. Materials would be removed directly from buildings under deconstruction and reused with minimal processing.

But there is much work to be done in systematising the recovery, grading and certification of salvaged building elements: “For secondary materials to compete strongly in the construction materials marketplace, technical, operational, social, cultural, regulatory and economic limitations need to be overcome,” UNEP’s 'Building Materials and the Climate' concludes rather glumly.

Nevertheless, wheels are slowly turning. In the UK, DISRUPT (the Delivering Innovative Steel Reuse Project), led by the Alliance for Sustainable Buildings Products, aims to facilitate the direct reuse of steel components. It estimates that by 2050, 45 per cent of all steel specified in construction could be from salvaged stock, and DISRUPT has created a toolkit on reuse for those in the steel supply chain.

In a similar vein, InFutureWood is a pan-European research project that aims to identify, and overcome, barriers to the direct reuse of timber in buildings. It is examining the design of timber structures for disassembly, the development of new construction products from salvaged wood, and processes for grading salvaged wood.

New research also suggests that the direct reuse of concrete components is more practical and feasible than we realise. Reusing timber has a double wind of preventing the need to make new products, and preventing the release of biogenic carbon, as most timber waste currently gets burned for energy or downgraded into short-lived products.

Materials from the biosphere

After the technosphere, our next port of call might be biobased materials that sequester carbon and can be produced in an ecologically sensitive manner, ideally from agricultural or forestry co-products. There is no shortage of such materials. Each year an estimated 140 gigatons of biomass by-product is generated worldwide. Scientists have looked at the construction potential of waste materials as varied as corn cob, reeds, miscanthus and sunflower stalks, with varying conclusions about their degree of technical readiness.

“The more construction becomes based on natural materials, the more we should start to think of it as agriculture,” says Will Hawkins.

Fast-growing biobased materials have the potential to achieve a net cooling effects faster due to their short rotation periods. Timber is not carbon neutral on short time frames – the climate benefit of wood products is only realised if or when another tree grows, which takes decades.

Straw and other agri-waste products

EcoCocon’s pioneering straw bale-based construction system. Photo: EcoCocon

Straw is the dry, hollow stalk leftover after the grain and chaff have been removed from crops such as wheat, oats, rye, and barley. It can provide infill insulation, usually in conjunction with a timber frame, and can be used structurally too.

A 2021 paper titled, ‘Land availability in Europe for a radical shift to biobased construction’, concluded that, compared with timber, hemp and cork: “Straw can be strongly recommended for large-scale construction and renovation since it has the highest cumulative carbon storage potential until 2050. Moreover, it is a by-product of wheat farming whose only use is animal bedding. Using it for construction would not change the amount of land used or the intensity of wheat production. It would, however, provide additional economic value to farmers.”

Calculations by the sustainable building consultant John Butler have concluded that the UK has enough straw right now to build 39,000 semi-detached homes each year, assuming just 5 per cent of annual wheat straw production (the lower value portion) is used for construction. The Slovakian company EcoCocon, which produces prefabricated wall panels with straw insulation, has now delivered more than 56,000 square metres of panel to over 430 projects across Europe and the US.

By-products from forestry and the processing of wood products also show significant potential. Wood foams are one recent innovation. A 2017 report from ARUP looks at the potential to create building materials from organic wastes.

However, great care is needed when labelling any biobased material as ‘waste’, as these materials can add economic value to existing production systems and thus facilitate the continuation or expansion of ecologically damaging practices. For example, by-products of deforestation-linked palm oil production have been mislabelled as waste to facilitate their greenwashing.

Coconut

Most of the demand for new construction in the coming decades will come from the Global South. The rapid development of sustainable materials in these regions would allow them to leapfrog the use of polluting, non-renewable materials. Coconut husks are one such material, with a high lignin content that makes them tough and stiff.

In the Philippines, eight million tons of coconut husk (80 per cent of the total volume) reach their end-of-life rotting on coconut farms. Coconut husk panels can meet or exceed the mechanical performance and durability of timber- based panels, while coconut fibreboards exhibit good hygrothermal performance in hot, humid conditions.

Research comparing the life cycle impacts of a coconut-based wall assembly with bamboo, cross-laminated timber and traditional timber boards found that coconut performed best across most environmental measures, including global warming potential, energy demand, acidification, eutrophication and freshwater consumption.

Cocoboard, a panel made from coconut husk fibres by Swiss company Naturloop. Photo: Naturloop

Hemp

After waste products, our next preference is for low carbon materials that require minimal land, or even better, that regenerate land or increase biodiversity in existing farmed systems.

Hemp is one such crop. Hempcrete is a non-structural material made from mixing the shiv (the woody interior of the hemp stalk) with a lime binder. It can be cast in formwork around a timber frame and provide insulation. Hemp fibre can be used to make loose-fill and batt-type insulations. Hemp lime boards can also be produced using hemp dust, a by-product, while hemp-based OSB is also under development.

However, the carbon emissions caused by lime production means that a big expansion of lime use is not compatible with a net zero society. So, we should move away from lime-based applications of hemp. Hemp can be grown in rotation with other crops. It improves soil health and yields of follow-on crops, and can be used to rehabilitate contaminated brownfield sites.

Self-builder James Byrne chose hemp-lime construction for his passive house in County Longford, published in issue eight of Passive House Plus.

The Tradical Hemcrete is mixed on site with water and poured into timber-shuttering against the timber frame structure.

Research by Material Cultures estimates that it would take 207 kha of land in the northeast and Yorkshire region (totalling about 8.6 per cent of land area – or 26 per cent of the arable land – in the region) to provide enough hemp fibre for all new homes in the region. Hemp shiv and dust would be generated too, and the latter would produce enough lining board to build 30,000 homes per year.

Despite the potential, the development of hemp as a building material is currently highly restricted across Europe due to stringent legislation around its cultivation.

Reed and other paludiculture materials

About 10 per cent of Europe’s land area is peatland, but approximately 50 per cent of this peatland is degraded and so it releases, rather than stores, carbon. If global peatland emissions continue unabated, they will consume 41 per cent of the world’s carbon budget for restricting global warming below 1.5°C.

‘Rewetting’, which is to say raising the water table by blocking drains, can protect and expand carbon stores in peat soils. Estimates suggest that rewetting just 3 per cent of agricultural land in Europe could reduce agricultural greenhouse gas emissions by 25 per cent. It would also help to restore biodiversity and protect water quality.

But rewetting is controversial – farming organisations fear it means removing land from productive agriculture. One solution is paludiculture, or the farming of wetlands. Paludiculture can produce food crops as well as materials for construction.

Research by Material Cultures and Bauhaus Earth looked at the potential for paludiculture at Serntizmoor, an area of peatland north-east of Brandenburg, Germany. This area was heavily drained in the past and has more recently been rewet for both ecological restoration and for paludiculture (in particular, for sedge grass and reed cultivation).

As part of their research, Material Cultures and Bauhaus identified the following materials that could potentially be produced at the site:

- typhaboard: a structural sheathing board made using cattail chips bound with magnesite (still to be formally certified)

- engineered timber produced from alder grown in wetlands

- rigid and flexible insulation batts made from grasses, as is the case with Gramitherm

- rigid insulation panels made from reed

- insulating fibre foam boards made from grass

- fibreboards made from reed

Material Cultures says that their 80-hectare study site could provide enough material to build sixty houses each year, with the inclusion of a 10 per cent biodiversity buffer zone.

They say challenges to the uptake of such materials include lack of consumer demand, cultural misconceptions and limited manufacturing capacity.

In 2020, a demonstration paludiculture tiny house was built in Germany, incorporating blown cattail insulation, reed thatching, meadow grass batts, and alder plywood panels. While still a new concept, paludiculture offers the potential to create new and sustainable building materials from more ecologically regenerative forms of land use.

German company Claytec offers a wirestitched reed building board for internal insulation, paired with clay plasters. Photo: Claytec GmbH

Bamboo

Bamboo is a fast-growing grass with a woody stem that can be used for construction. There have been significant advances in its use as a structural material in the past two decades.

Bamboo can be used for structural walls, roofing, interior panels, and floors. It can replace up to 70 per cent of steel applications. Bamboo poles can be used for a range of scaffolding, sheer wall and complex structures.

There are about 1,400 species of bamboo but only a few dozen are suitable for construction; these are typically indigenous to tropical and sub-tropical climates.

One disadvantage of bamboo is that it weathers rapidly in humid climates unless treated with synthetic chemicals and high pressure drying. These significantly increase its carbon footprint and can even make its emissions comparable to steel before any sequestered carbon is subtracted. The development of low carbon, eco-friendly treatments as well as renewable-powered manufacturing can reduce this.

The technical performance of bamboo species varies by region, and further work is needed to develop construction methods, standards and certifications. Per hectare, bamboo forests sequester about 1.33 times as much carbon as tropical rainforest per year.

Bamboo flooring features in the certified passive Cannock Mill co-housing scheme in Colchester, published in issue 40 of Passive House Plus. Photo: Adelina Iliev

Earthen materials

Besides biobased crops, there is also potential for sustainable use of non-renewable earth materials that are sourced locally and require minimal processing. Around 8-10 per cent of the world’s population live in earth-based structures, but in developing countries, earthbased masonry can be associated with poor durability, moisture issues, high maintenance and low social class. However, there is growing research and development into innovating earth-based construction with contemporary techniques and standards.

There are clear carbon advantages to such materials when they can be employed without processing: earthen bricks that are left to cure in the sun, in hot countries, have an embodied carbon of between 1.2 and 5.4 kg CO2 per kg of earth block, compared to 230- 250 kg for earthen bricks cured in gas-fired kilns. Portland cement is sometimes added to earth masonry as a binder to improve durability, so rapid development of alternative low carbon binders is needed.

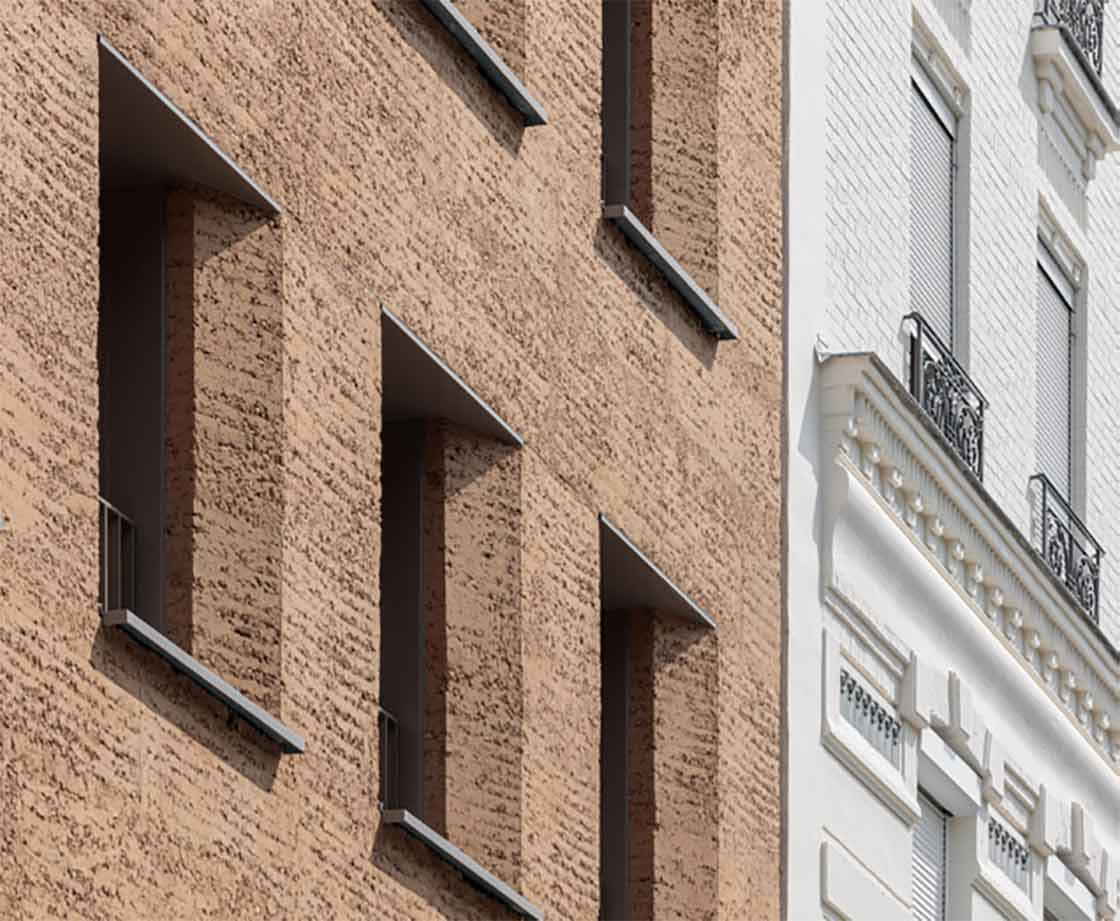

17 Rue des Quatre-Cheminées, designed by Déchelette Architecture in 2021 and located in the Parisian suburb of Boulogne-Billancourt, is a four-storey building, including eight social housing units and a shop, using a timber structure, with extensive use of prefabricated rammed earth. Photo: Salem Mostefaoui / Déchelette Architecture

Cut stone

Cut stone is another earthen material with significant potential. Its climate advantages are derived from the fact it can simply be quarried and cut – no high temperature processing is required. Research shows that cut stone has 1.43 times less greenhouse gas emissions than CLT over a 50-year time horizon, and 2.73 times less than concrete with a low carbon GGBS binder. Due to the intensity of extraction in concentrated locations, any impacts on biodiversity are localised. One estimate says that 50,000 m3 of cut stone can be harvested per hectare each year at appropriate sites, compared to 3.5 m3 for CLT. Modern stone mining often happens completely underground, minimising impact on the land above. Use of electrified machinery in stone mines and quarries is now more common. Stone is heavy and thus transport is responsible for a significant proportion of its carbon footprint, so it is best used locally. One region particularly rich in stone is Paris, which has a long history of stone construction.

Cutting edge cut stone: Amin Taha + Groupwork’s 15 Clerkenwell Close in London features a façade of raw quarried limestone. Photo: Timothy Soar

An ecological material palette for the future

The above list of materials is not intended to be exhaustive or authoritative, but to broaden our view of what our palette of low carbon, ecologically constrained materials could look like. All the above materials are currently being used to some extent, but most not at scale.

What might we build with, and how might we use materials, if we specified in response to local agriculture, ecology, and carbon flows, rather than global markets? Could our choice of materials change annually, or even seasonally, depending on local ecosystems? How could we make such a product system viable and affordable?

Right now, many bio-based materials are too expensive – likely because they are niche or labour intensive – so cheaper and more polluting alternatives are often specified instead.

Various timber elements would be part of this mix too, of course, but we do not include them as we have written extensively about timber elsewhere. Many of the novel materials we have mentioned need further work. UNEP’s Building Materials and the Climate report says that, “standardisation of performance, integration into building codes, broad industry upskilling, marketing and financial incentivisation,” are all needed. What’s more, without strong legal protection for nature and a shift to more regenerative forms of agriculture and forestry, a rapidly increased demand for biobased materials has the potential to do more harm than good to the living world.

Neither a radical shift to ecological materials nor ecological thinking about how we use materials will happen overnight. In time, we hope that materials like steel, concrete, aluminium, and plastic will become choices of last resort, used sparingly, at the bottom of our hierarchy. Nevertheless, their use may need to be prioritised for critical infrastructure, such as sea defences or railway infrastructure and, for now, they are likely to be used widely while ecological alternatives scale up, and become cheaper. As such, it is critical that we decarbonise conventional materials as quickly as possible, too.

A 2022 report written for the AECB by energy consultant David Olivier evaluates pathways to decarbonise cement and concrete, fired clay bricks, steel, aluminium and other common high energy materials. Efficient use of conventional materials can go a long way to reducing the carbon footprint of construction. For example, research carried out by the AECB, Tim Martel and John Butler, and funded in separate phases by the Passive House Association of Ireland and Irish Timber Frame Manufacturers’ Association, found that a house built with single leaf block-on-flat walls with EPS insulation and silicone render, emitted 1.6 tonnes less CO2 than the same house built with a brick-clad cavity wall, and 6.8 tonnes less than an Insulated Concrete Formwork wall.

Of course, building nothing and building less are the simplest and most effective ways to reduce the environmental footprint of materials. They require no innovation whatsoever.

Unchecked growth will eventually overwhelm any living system no matter how ‘sustainable’ or ‘regenerative’ its products appear. But if we prioritise sufficiency, then a world where we can meet our genuine need for building materials in harmony with local ecosystems may be achievable.

This article was commissioned for Passive House Plus by the AECB.