- New build

- Posted

Deep green passive house defies all weather

With Old Holloway Cottage, located in rural Herefordshire, architect Juraj Mikurcik and his wife Joyce have lovingly crafted a beautiful-yet-simple passive home that is constructed from timber, insulated with straw, and finished with a palette of natural, durable materials — and all for a surprisingly small budget.

Click here for project specs and suppliers

Building: 99 sqm timber frame bungalow

Location: Little Birch, Herefordshire

Completed: October 2017

Cost: £135,000 (construction only, including VAT rebate)

Standard: Passive house certified

£O for space heating (spent so far on timber for wood burning stove, see 'in detail' below for more)

Having designed a number of passive house buildings for his employer Architype while enduring life in a chilly old cottage that cost £1,500 each winter to heat, architect Juraj Mikurcik and his wife Joyce Freeman had been dreaming of building their own passive house.

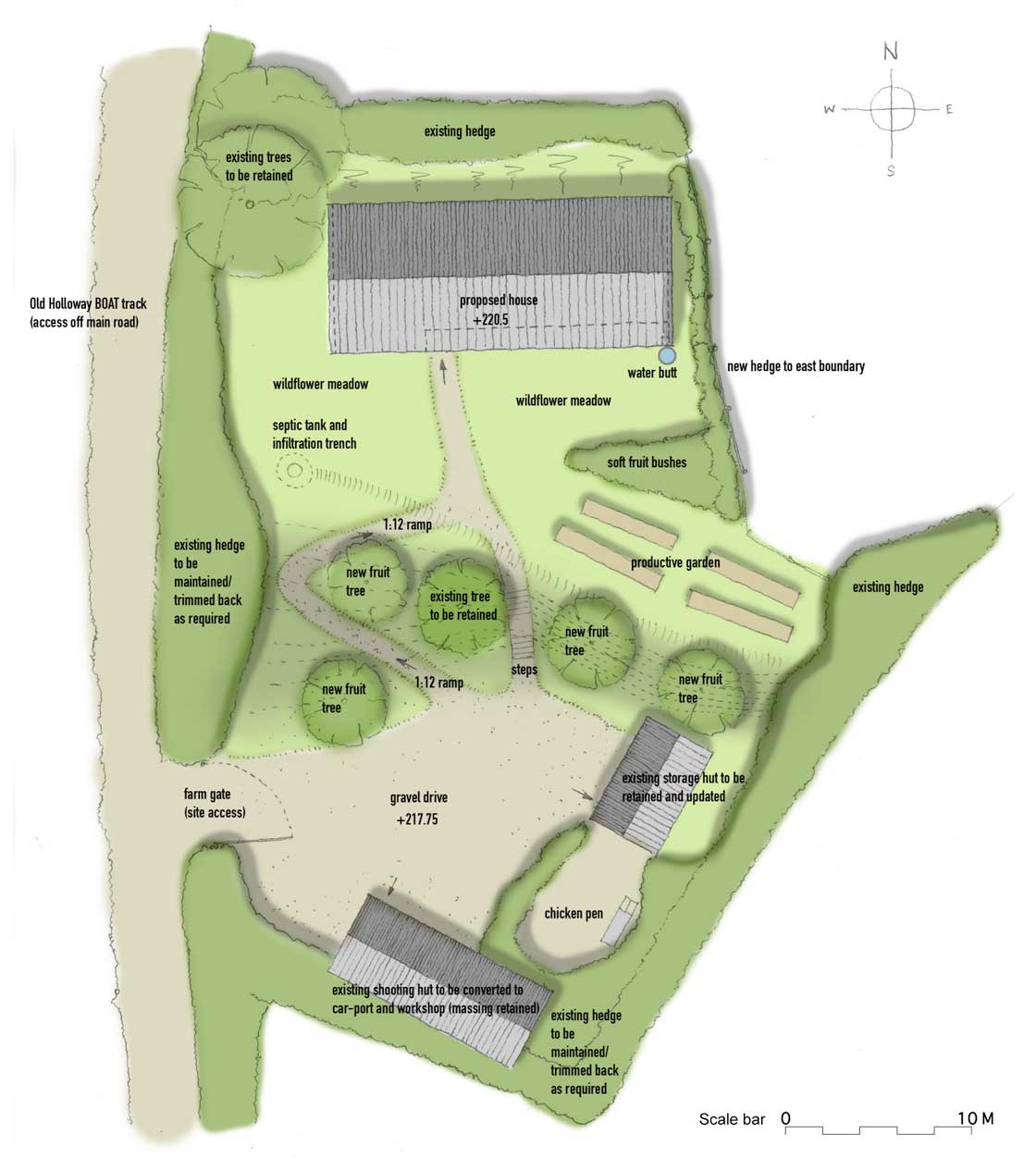

Affordable plots for self-builds are a rare find in rural Herefordshire, but Juraj and Joyce were lucky enough to find the perfect site, by complete chance – they happened to pass it on a bike ride. The site, on a south facing slope with wonderful views out over the countryside, looked unused. And it was: it turned out to house a redundant shooting hut belonging to the Duchy of Cornwall, who are also Architype’s landlord at their nearby Upper Twyford office (the Duchy owns a lot of land in the area).

The Duchy agreed to sell the land, but Juraj and Joyce would have to get its approval for their design before the house was submitted for planning permission.

The Duchy required the building to look simple and modest – the former shooting hut was a low-roofed timber shed, and they wanted the house to reflect this agricultural aesthetic. This ruled out Juraj’s original, more overtly contemporary design with its monopitch green roof and distinctive glazing.

The Duchy’s stipulations worked to Juraj and Joyce’s advantage though, as valuation of the plot reflected the fact that though quite large, it was only going to accommodate one modest three-bed home, and not the three-garage McMansion (or two) that might otherwise have been built on a plot of this size.

Juraj and Joyce were keen to build at the top of the plot, to take maximum advantage of the view. As there is a house behind them, they were limited to a single storey so as not to impinge excessively on their neighbours.

The design they settled on was a long, low, timber clad bungalow with a simple corrugated steel roof, the timber to be charred, and the roof painted black – a look Juraj liked, and also one that helped the building recede visually into its surroundings, in line with the Duchy’s preferences.

Small detached bungalows inevitably have pretty poor form factors, and with a ratio of 4.6 this one is certainly not ideal for a passive house (see ‘Explained’). But Juraj and Joyce did manage to achieve the standard without appearing to strain either the design or the choice of materials.

Straw and timber construction

This article was originally published in issue 25 of Passive House Plus magazine. Want immediate access to all back issues and exclusive extra content? Click here to subscribe for as little as €10, or click here to receive the next issue free of charge

For the build, Juraj was keen to try a modular, prefabricated straw-and-timber system called Ecococon that’s manufactured in Lithuania. “I encountered Ecococon via my friend Bjørn Kierulf in Slovakia, he had been using it for the past five years or so,” he says.

“From our point of view, it combines low impact, renewable materials with accuracy and speed. I had tried to specify this system on previous Architype projects, to no avail, so this was the perfect opportunity to try it out – and we were the first to use the system in the UK.”

Although committed to the use of natural materials, and in particular timber (the material most favoured by Architype), Juraj is not keen on the slightly ‘hollow’ finish he feels you sometimes get from timber frame with plasterboard linings.

“I wanted to achieve a solid feel to the house if possible. Coming from central Europe I’m quite used to masonry buildings. The clay plaster applied straight on to Ecococon panels creates a really solid wall. Also the Fermacell linings applied to internal partitions are double the density of standard plasterboard, so the building ends up feeling a lot more solid.”

-

Installing the 250mm Isoquick EPS insulated foundation system

Installing the 250mm Isoquick EPS insulated foundation system

Installing the 250mm Isoquick EPS insulated foundation system

Installing the 250mm Isoquick EPS insulated foundation system

-

Pouring the concrete slab

Pouring the concrete slab

Pouring the concrete slab

Pouring the concrete slab

-

The walls of the house were built using Ecococon, a modular prefabricated straw-and-timber system

The walls of the house were built using Ecococon, a modular prefabricated straw-and-timber system

The walls of the house were built using Ecococon, a modular prefabricated straw-and-timber system

The walls of the house were built using Ecococon, a modular prefabricated straw-and-timber system

-

Econocon also supplied the roof system, which features I-joists and a thermalbridge free cantilevered roof overhang along the south

Econocon also supplied the roof system, which features I-joists and a thermalbridge free cantilevered roof overhang along the south

Econocon also supplied the roof system, which features I-joists and a thermalbridge free cantilevered roof overhang along the south

Econocon also supplied the roof system, which features I-joists and a thermalbridge free cantilevered roof overhang along the south

-

Cellulose expert Gordon Lewis pump-filling the Warmcel cellulose insulation into the roof

Cellulose expert Gordon Lewis pump-filling the Warmcel cellulose insulation into the roof

Cellulose expert Gordon Lewis pump-filling the Warmcel cellulose insulation into the roof

Cellulose expert Gordon Lewis pump-filling the Warmcel cellulose insulation into the roof

-

Internal clay plastering directly onto the straw, with reinforcing mesh visible

Internal clay plastering directly onto the straw, with reinforcing mesh visible

Internal clay plastering directly onto the straw, with reinforcing mesh visible

Internal clay plastering directly onto the straw, with reinforcing mesh visible

-

The locally-sourced cedar cladding was all charred on-site with a blowtorch, to give a pleasing, slightly-textured, and highly durable finish

The locally-sourced cedar cladding was all charred on-site with a blowtorch, to give a pleasing, slightly-textured, and highly durable finish

The locally-sourced cedar cladding was all charred on-site with a blowtorch, to give a pleasing, slightly-textured, and highly durable finish

The locally-sourced cedar cladding was all charred on-site with a blowtorch, to give a pleasing, slightly-textured, and highly durable finish

-

The locally-sourced cedar cladding was all charred on-site with a blowtorch, to give a pleasing, slightly-textured, and highly durable finish

The locally-sourced cedar cladding was all charred on-site with a blowtorch, to give a pleasing, slightly-textured, and highly durable finish

The locally-sourced cedar cladding was all charred on-site with a blowtorch, to give a pleasing, slightly-textured, and highly durable finish

The locally-sourced cedar cladding was all charred on-site with a blowtorch, to give a pleasing, slightly-textured, and highly durable finish

-

Alan Clarke commissioning the ventilation system

Alan Clarke commissioning the ventilation system

Alan Clarke commissioning the ventilation system

Alan Clarke commissioning the ventilation system

https://mail.passivehouseplus.co.uk/magazine/new-build/deep-green-passive-house-defies-all-weather#sigProIdd1a54773ae

Ecococon is a screw-together modular system, comprising wooden frames densely packed with straw to achieve precise sizing, and consistent thermal and moisture properties.

End panels and window reveals are faced with 12mm plywood, but otherwise the timber structure does not cross the straw layer, minimising thermal bridging, and enabling the system to achieve passive house certification.

Everything in Juraj’s design was sized to fit Ecococon’s standard 600mm and 800mm modules, which proved much more cost-effective than getting bespoke module sizes made up. The design was all communicated in the SketchUp 3D modelling software, and Ecococon supplied a colour-coded set of build instructions.

Structure and insulation

Inside, the main labour of love was the polished concrete slab – ground by Juraj over an uncountable number of hours.

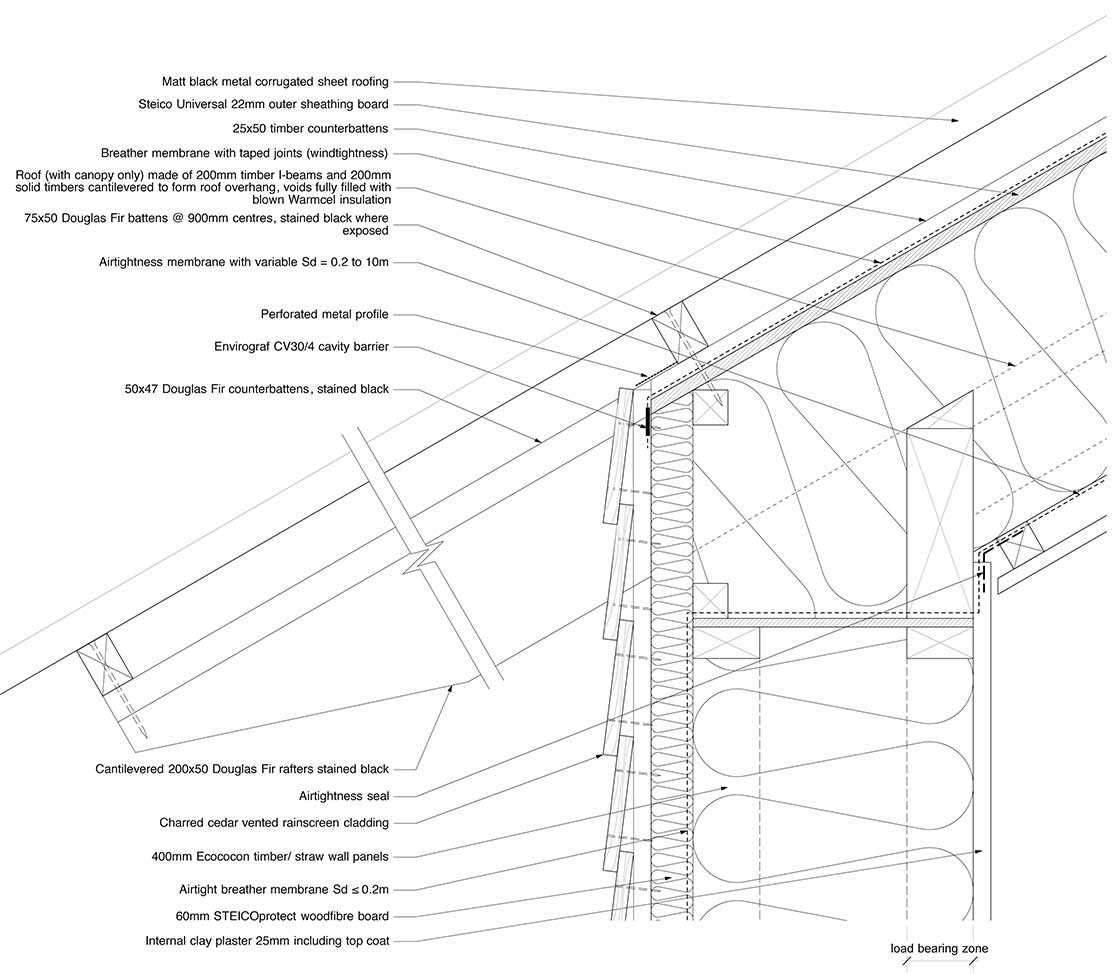

To achieve the passive house standard, the insulating performance of roof and walls had to be increased slightly on Ecococon’s standard spec, but this worked well with other aspects of the design.

For example, as Juraj and Joyce were building to the passive house standard, the Ecococon system required an airtightness membrane sitting outside the straw layer (so the clay plaster could be applied directly to the straw internally). This in turn made it necessary to add wood-fibre boards to the outside of the straw and membrane, otherwise a sharp temperature drop could have created a risk of interstitial condensation here. But this extra layer of insulation also brought the wall U-value down to what was required to meet passive house requirements.

To get a low enough U-value in the roof, I-joists were used, fully filled with 400mm of Warmcel. “On the plus side this allowed us to achieve a thermal bridge-free cantilevered roof overhang along the south, because there was enough depth to incorporate rafters without bridging right across the roof insulation,” Juraj says.

-

The internal clay plaster

The internal clay plaster

The internal clay plaster

The internal clay plaster

-

The internal clay plaster

The internal clay plaster

The internal clay plaster

The internal clay plaster

-

The straw-insulated walls with reed mat reinforcement

The straw-insulated walls with reed mat reinforcement

The straw-insulated walls with reed mat reinforcement

The straw-insulated walls with reed mat reinforcement

-

The charred cedar cladding

The charred cedar cladding

The charred cedar cladding

The charred cedar cladding

-

Douglas fir for internal doors

Douglas fir for internal doors

Douglas fir for internal doors

Douglas fir for internal doors

https://mail.passivehouseplus.co.uk/magazine/new-build/deep-green-passive-house-defies-all-weather#sigProId61dd0296ab

Ecococon designed and supplied all the roof structure, including pre-sawn beams, wall plates and so on. “There was only one main delivery to worry about, and I wanted to keep the structural packages with one subcontractor rather than splitting it up and risking finger pointing if anything didn’t fit. I’d recommend this approach every time,” he says.

The floor construction is an Isoquick raft system, essentially a tub of EPS insulation with a concrete slab poured above and within the insulation. Compacfoam high density EPS is installed within the system under door thresholds to support their weight.

The straw panels were set out from the floor slab in order to align the straw layer with the returns of the under-slab insulation.

Ecococon confirmed that the panels would comfortably support the roof with this arrangement.

Passive performance

For winter warmth and comfort, alongside the high levels of insulation, low thermal bridging and airtightness, the bungalow employs extensive south glazing.

High performance windows are not cheap, but oh, they are lovely to have. They will never be as well-insulated as a passive house wall though, so it is crucial to design glazing carefully: overdoing it quickly blows the financial and energy budgets, and risks summer overheating too.

“We’ve used a few ground rules for window design: keep things simple, minimise mullions [the vertical bars between panes of glass], have opening lights only where needed, keep sizes to sensible dimensions, and provide adequate shading.”

Nonetheless, Juraj and Joyce could not resist including large sliding glass doors in the main living area. “Luckily we were able to orientate the house facing perfect due south, which allowed us to design in shading relatively easily, while enjoying a lot of solar gains in winter.”

The large roof overhang along the south of the house provides simple and effective shading without any need for blinds, and it extends the usable living space too. “Great for informal sitting, chilling and eating,” Juraj says.

The one south window that is not shaded by the roof has an integral external roller blind. The windows also have deep reveals to cut ‘sideways’ solar gain during summer mornings and evenings, while east and west windows also have manually operated roller blinds.

The clay plaster and Fermacell-lined partitions mean that despite the timber and straw, the house is not a lightweight construction, and these heavier building elements provide thermal mass that can help to smooth out internal temperatures by absorbing heat and releasing it slowly.

But the majority of the thermal buffering is provided by the exposed slab: “We chose to use a concrete slab as the base for our house for a couple of reasons: once ground down, it would provide a durable finished floor surface, and it would provide useful thermal mass in an otherwise medium density construction.”

The exposed concrete helps to moderate daytime peaks, but as Juraj points out, withthermal mass, adequate provision for ‘night purging’ is essential to ensure heat does not build up. He can achieve this by opening all windows at night, providing good cross ventilation.

Metal mesh fly screens over the bedroom windows enable night ventilation without insects getting in — and also add privacy and cut out some solar gain during the day. This works so well that Juraj and Joyce have retrofitted similar screens to other windows.

Wood-burning stove

Ecococon is a screw-together modular system, comprising wooden frames densely packed with straw.

Not much space heating is required, and most is provided by a small 4kW wood-burning stove in the main living space – something Juraj wanted to indulge in, despite the inevitable extra fiddle of installing a stove in an airtight building (eased here by using a single flue with separate, in and out channels like the balanced flue for a gas boiler). The stove heats the house directly – there is no back boiler or underfloor heating.

Top-up space heating — to bathroom towel rails only — and hot water is supplied by an Ariston 200L hot water cylinder that is heated by an integrated air source heat pump. The heat pump runs for about a third of the time in winter, much less in summer, and is quiet, with a hum similar to a fridge. The Zehnder ComfoAir160 heat recovery ventilation system is also pretty much inaudible.

The build

The main contractor on the project was legendary local builder and passive house specialist Mike Whitfield. The Ecococon system was a first for Mike, who generally builds his own timber frame structures on site, but he was happy to give something new a go here.

Juraj was impressed by the speed of construction. “It took us only three days to assemble all the external walls, two internal load bearing walls and the main glulam ridge beam,” he says. Everything fitted perfectly, Juraj says, and the building was watertight in just four weeks.

Nevertheless in the short period at the start before the roof and external sheathing went on, the structure was very vulnerable to any rain, making those weeks “a bit hairy”, as Mike put it. The structure had to be kept meticulously covered. In one small spot the wrapping must have failed, as Juraj later found that a patch of straw had sprouted, and had to be removed and replaced with cellulose insulation.

-

Airtightness tapes pre-fitted on Smartwin passive house certified timber windows

Airtightness tapes pre-fitted on Smartwin passive house certified timber windows

Airtightness tapes pre-fitted on Smartwin passive house certified timber windows

Airtightness tapes pre-fitted on Smartwin passive house certified timber windows

-

Plywood box window reveals

Plywood box window reveals

Plywood box window reveals

Plywood box window reveals

-

Energy consultant Nick Grant uses a smoke pencil to look for air leakages around the windows

Energy consultant Nick Grant uses a smoke pencil to look for air leakages around the windows

Energy consultant Nick Grant uses a smoke pencil to look for air leakages around the windows

Energy consultant Nick Grant uses a smoke pencil to look for air leakages around the windows

https://mail.passivehouseplus.co.uk/magazine/new-build/deep-green-passive-house-defies-all-weather#sigProId2e296314b4

The modular system was easier to handle than full-sized timber panels would have been – the biggest section weighed around 120kg (this was less than half the weight of the glass sliding doors, which had to be unloaded at a nearby industrial estate). Most of the panels weighed around 60-70kg, so were relatively easy to move. The combination of a modular system and single-storey construction thus averted the need for lifting equipment. Given that access was tight, this was a great advantage.

Mike’s reputation for meticulous detailing was borne out with the airtightness result of 0.38 air changes per hour. “Bearing in mind the unfavourable form factor, and the fact that we used mainly membranes for airtightness – and fitted a wood stove – we were really pleased. It really is a credit to the whole Mike Whitfield building team,” Juraj says.

Natural finishes

The use of low toxicity, natural materials was very important to Juraj and Joyce, and they have put together a relatively small number of lovely materials, to great effect.

On the outside of the house, the charred finish was something Juraj had always wanted to try, but never persuaded a client to specify. The locally-sourced cedar cladding was all charred on-site with a blowtorch, by Juraj and a couple of friends to give a pleasing, slightly-textured, and highly durable finish.

Of course many designers enjoy the chance to be truly hands-on, and Juraj made the absolute most of the opportunity.

Inside, the main labour of love was the polished concrete slab – ground by Juraj over an uncountable number of hours. But the beauty of the innumerable colours of the stones shining through the sealed finish is unarguable.

Also very hands-on was the clay plastering. Juraj got the chance to work alongside an expert, Roman Miškov from Slovakia, and the two of them completed the plastering together. The clay is mixed with natural pigments to give several soft, earthy colours – and for some of the walls, the finish included chopped straw, which adds a lovely hint of sparkle when the light catches it.

Above the main living area, the cathedral ceiling is softened with a pattern of untreated redwood battens, which also help with acoustics. And apart from the insulation under the slab, and the seal on its surface, very few petrochemical products were used in this build.

The clay plasters are either left natural or finished with natural pigments. Exposed timber is oiled with Osmo oil, and Auro paints were used on plasterboard ceilings – both these product ranges are mainly plant-based, or use natural products such as milk casein.

Wonderful - but how affordable?

As well as quite a bit of hands-on involvement with the build, a lot of time was spent creating the very particular finishes — the clay plaster, charred wood and polished concrete — making it very much Juraj and Joyce’s house.

The construction costs have been totted up by Juraj as coming to £150,000 (£135,000 after a VAT refund, as they were self-builders) for a 99 square metre house. It’s always tricky to compare costs across projects, but with its simple, modest form, a passive house build of similar design realised via more familiar construction methods, for a client who did not want to get so involved on site, should be at least as affordable.

So many self-build projects run away with themselves and end up larger, and therefore more expensive than really makes sense. “My top tip to self-builders is: re-evaluate how much space you actually need,” Juraj says. The smaller the build, the more detailed control you will have, and the more budget you’ll have left to spend on the best components, on beautiful finishes – or indeed, on just enjoying life in your new home.

Selected project details

Clients: Juraj Mikurcik & Joyce Freeman

Architect & passive house consultant: Juraj Mikurcik

Energy rating assessment: Energy Calculations Ltd

Passive house certifier: WARM

Timber frame: Ecococon

Timber frame technical support: Bjørn Kierulf/Createrra

Mechanical services consultants: Alan Clarke & Nick Grant

Contractor (up to lock-up stage): Mike Whitfield Construction Ltd

Mechanical contractor: Robert R McGowan Ltd

Electrical contractor: Monnow Electrical Services Ltd

Airtightness testing: Paul Jennings/Encraft & Melin

External woodfibre insulation: Steico, via Ecococon

Blown cellulose insulation: Warmcel, via PYC

Insulated foundation system: Isoquick UK

Thermal breaks: Compacfoam, via Green Building Store

Windows, doors & sliding doors: Smartwin, via Hoblina

Timber joinery: JM Joinery

Airtightness products: Siga & Pro Clima

MVHR: Zehnder, via Green Building Store

Wood burning stove: Morso S11-43, via Prince & Pugh

Stove flue: Poujoulat UK

Hot water cylinder w/integrated heat pump: Ariston Nuos 200, via Graham The Plumbers Merchant

Internal stud linings: Fermacell

Ceiling linings: British Gypsum

Flooring: FILA clear wax, via Mandarin Stone Monmouth

Clay plasters: Picas

Clay plasterer: Roman Miškov/Bioline

Timber cladding: Cilfiegan Sawmill

Timber decking: Vastern Timber

Timber cladding & decking fixings: Sigha, via Russwood

Pre-mixed concrete: Radbournes Hereford

Custom lights: Lock Lamp

Corrugated metal roofing: Thomas Panels & Profiles

Eco paints: Auro, via The Green Shop

Natural wood stains: OSMO, via Gibbs & Dandy

Finance: Ecology Building Society

Living in Old Holloway house

The first year threw extremes of both heat and cold at Old Holloway cottage – so how did it fare?

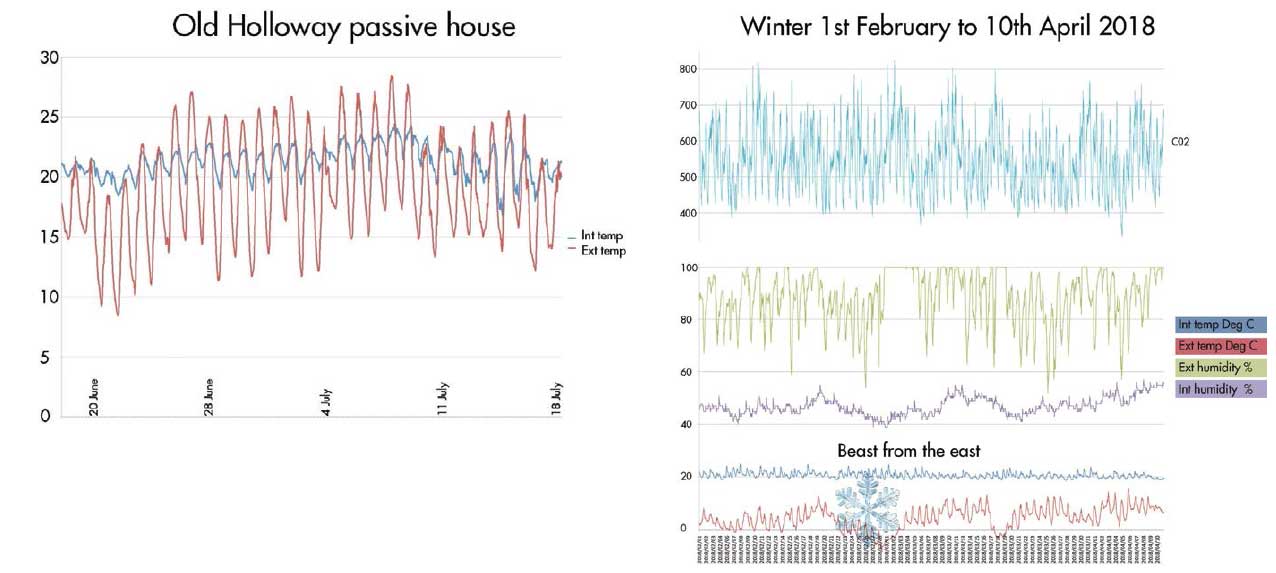

Juraj and Joyce moved in during the of summer 2017, but the house maintained a steady 20 to 21C, without heating, well into the autumn. It wasn’t until November that they felt cold enough to light the stove, which they continued to do every couple of nights or so through the winter. They report that it generally only needs to burn for an hour if the sun has been out, but longer when the weather has been grey.

Even when the ‘beast from the east’ struck last February, indoor temperatures were remarkably even. Not only was that episode bitterly cold, it was also very windy: the kind of weather where airtightness comes into its own. So far Joyce and Juraj haven’t spent a penny on firewood, as the first winter only used up around one cubic metre of construction offcuts, and Juraj reckons there is another three winters’ worth left — a dramatic contrast to costs at their previous home.

Between the south-facing glazing, the stove and any additional heat gains (e.g. from cooking), the living area tends to be a couple of degrees warmer than the bedrooms, which is how Juraj and Joyce — and indeed many people — like it.

And then of course there was 2018’s summer. Passive House Plus visited the house on a warm muggy day, and it felt pleasantly cool inside. And this is borne out by the monitoring results. Overall, PHPP predicted 0% overheating, and despite this year’s prolonged heatwave, this has been achieved, with internal temperatures remaining below 25C (the passive house definition of overheating) at all times.

While outside temperatures regularly hit 25C to 27C, inside the temperature generally peaked around 22C or 23C, with night purges bringing it back down to around 20C each night. As the hot weather carried on, indoor peaks to some extent reflected conditions at night: a spell in early July where night-time temperature lows outside started to edge upward saw indoor temperatures creep up too, towards 24C, but with outdoor daytime highs of 27 and 28, this still felt very comfortable, Juraj says.

In detail

Building type: 99 sqm timber frame bungalow

Location: Little Birch, Herefordshire, UK

Completion date: October 2017

Budget: £150,000 (£135,000 after tax rebate on materials for new self-build homes)

Passive house certification: Certified

Space heating demand (PHPP): 14.9 kWh/m2/yr

Heat load (PHPP): 12.0 W/m2

Primary energy demand (PHPP): 142 kWh/m2/yr

Heat loss form factor (PHPP): 4.54

Overheating (PHPP): 0%

Airtightness (at 50 Pascals): 0.38 ACH final air test

Energy performance certificate (EPC): C 78

Measured energy consumption: Calculated space heating demand based on 1m3 of burnt wood over the winter heating season (assumed calorific value 1,800kWh per tonne and weight of 500kg/m2 timber) is 9.5 kWh/ m2/yr. Ariston Nuos 200 water cylinder with integrated air source heat pump consumed 1,641 kWh or approx. 32kWh per week between July 2017 and July 2018, providing all domestic hot water and some space heating via towel rails in bathrooms for six months of the year. Difficult to estimate the portion of energy used for heating the towel rail as it is not sub-metered. Conservative estimate is approximately 15% of output to towel rails and 85% for domestic hot water.

Thermal bridging: Ecococon timber/ straw system is certified by the Passive House Institute with confirmed Y-values for typical junctions, most of which are negative. These values can simply be used in PHPP. Example: external wall corner has a Y-value of -0.089 W/mK. The junction between the wall and insulated slab was modeled using PSI Therm, with Y-value of -0.004 W/mK. Woodstove flue Y-value was assessed as 1.1 W/mK and thermal bridge through one insulated SVP as 0.28 W/ mK. Doors are installed on Compacfoam EPS bearers (notched into Isoquick EPS foundation system) bolted to the edge of concrete slab. Window and door frames are partially insulated on the outside with wood fibre boards.

Energy bills (measured or estimated): Monthly electricity bill £55 (direct debit based on meter readings). This includes air source heat pump (providing domestic hot water and heated towel rails) and all domestic appliances, equipment and lighting.

Ground floor: 150mm compacted hardcore base followed above by 45mm sand blinding, 250mm Isoquick EPS insulated foundation system, 1mm DPM, 225mm reinforced concrete slab, ground finish & clear sealant. U-value: 0.095 W/m2K.

Walls: Rainscreen horizontal board on board timber cladding: 200x20 homegrown western red cedar from the Forest of Dean, charred on site. Majority of cladding is sealed with clear OSMO oil. All cladding fixed to 25x50mm vertical softwood battens using Sigha black finished 70mm long stainless-steel screws. Followed inside by Steico Protect T&G woodfibre board, stapled through DuPont™ Tyvek® and AirGuard® Pro airtight breather membrane to Ecococon panels. All joints in membrane taped with SIGA Wigluw tape. Ecococon timber-straw panels inside membrane, followed behind by internal clay plaster consisting of two 15mm coarse base coats with reinforcing mesh, 5mm fine undercoat and 1.5mm self-pigmented fine top coat with chopped straw for added sparkle. Reed mat reinforcement was applied to larger areas of timber (glulam lintels, ply window reveals) for improved key prior to plastering. U-value: 0.13 W/m2K.

Roof: Black factory painted corrugated steel sheet panels fixed to 75x50mm Douglas fir battens and 50x50mm softwood counterbattens, on SIGA Majcoat breather membrane, on 22mm Steico Universal woodfibre sheathing board. Roof rafters are 400mm deep Steico timber I-beams with gaps fully filled with Warmcel blown recycled cellulose. On the underside, SIGA Majpell 5 airtightness membrane is applied, with all joints taped with SIGA Sicrall 60 airtightness tape. Penetrations in membrane after installation of Warmcel sealed with SIGA Sicrall 170 airtightness tape. Uninsulated 50mm service void. Acoustic ceiling finish to the main open plan living space: hit & miss softwood battens of varying widths (50mm, 70mm and 100mm) and 20mm thickness, on black membrane. British Gypsum Wallboard plasterboard, taped & jointed to other spaces. Auro 321 Classic emission free emulsion paint on plasterboard. U-value of roof: 0.095 W/m2K

Windows, external doors, sliding doors: Smartwin passive house certified aluminium clad timber units, sealed with SIGA airtightness and wind-tightness tapes. Average window & door U-value: 0.76 W/m2K. Heating: Main space heating system: Morso S11 4kW woodstove with Poujoulat Efficience triple wall flue. No radiators or underfloor heating. Secondary heating system: stainless steel towel rails in bathrooms, running off domestic hot water system on a separate circuit. Domestic hot water is provided via Ariston Nuos 200 water cylinder with integral air source heat pump.

Ventilation: Zehnder Comfoair 160 Luxe MVHR system (via Green Building Store), with Lindab circular spiral bound metal ducting. Cascade system, supplying fresh air to habitable rooms and extracting from bathroom, shower room, utility and kitchen. Automatic summer bypass on MVHR.

Blinds: Sunstop (CZ) manual external fabric blinds (semi-translucent) integrated with window frames.

Green materials: Timber & straw wall panels; Fermacell dry lining boards; sheep wool, woodfibre and recycled cellulose insulation; clay plasters; barrier matting made from recycled tyres; locally sourced timber cladding; all timber sourced from PEFC/ FSC certified suppliers.

Image gallery

-

South west elevations

South west elevations

South west elevations

South west elevations

-

North east elevations

North east elevations

North east elevations

North east elevations

-

Foundation detail

Foundation detail

Foundation detail

Foundation detail

-

Sections

Sections

Sections

Sections

-

Slab edge Psi calculation

Slab edge Psi calculation

Slab edge Psi calculation

Slab edge Psi calculation

-

Window cill head details

Window cill head details

Window cill head details

Window cill head details

https://mail.passivehouseplus.co.uk/magazine/new-build/deep-green-passive-house-defies-all-weather#sigProId6e8ed495aa