- New build

- Posted

UK's largest passive building opens to 2,400 students and staff

Completed early this year, the new Centre for Medicine at the University of Leicester is by far the largest single building in the UK to meet the passive house standard — and not surprisingly, its design and construction posed tough new challenges for how to meet the rigorous low energy standard on such a large, complicated building.

Click here for project specs and suppliers

This article was originally published in issue 18 of Passive House Plus magazine. Want immediate access to all back issues and exclusive extra content? Click here to subscribe for as little as €10, or click here to receive the next issue free of charge

The Centre for Medicine at the University of Leicester represents a landmark for passive house in the UK. It is by far the largest single building to achieve passive house certification – around four times larger than its UK predecessors – and one of the first UK passive house buildings to engage with the world of mainstream commercial construction.

The Centre for Medicine brings together three academic departments at the university, previously housed in 19 separate buildings, and accommodates 2,400 people in a mixture of teaching, social, research and office accommodation.

As architect Jonathan Chadwick of Associated Architects explains, originally the University of Leicester wanted a ‘zero carbon’ building to act as the centre piece of their carbon reduction plan. However the architects and M+E engineers Couch Perry Wilkes together explained that zero carbon was a nebulous term and a carbon neutral building isn’t necessarily efficient and cheap to run. “Instead we advised the university that passive house should be the basis of the project as it has a proven track record for delivering comfortable, low energy buildings”, Chadwick said.

The Passive House Institute certified PR60energysave triple-glazed glass roof, as supplied by DVS Ltd

James Elliment from lead contractor Willmott Dixon believes this project exemplifies passive house’s next big challenge in the UK: the transition between small, mainly domestic buildings and large commercial projects.

“There is a huge difference in the way you construct large commercial buildings — the way you build, the supply chain, design and procurement.” Designers with experience of small-scale passive house may be less familiar with these mainstream, larger-scale systems. Meanwhile, mainstream contractors tend not to be familiar with the demands of passive house. All these challenges came into play with the Centre for Medicine – and all were successfully overcome, and the building has now been certified passive.

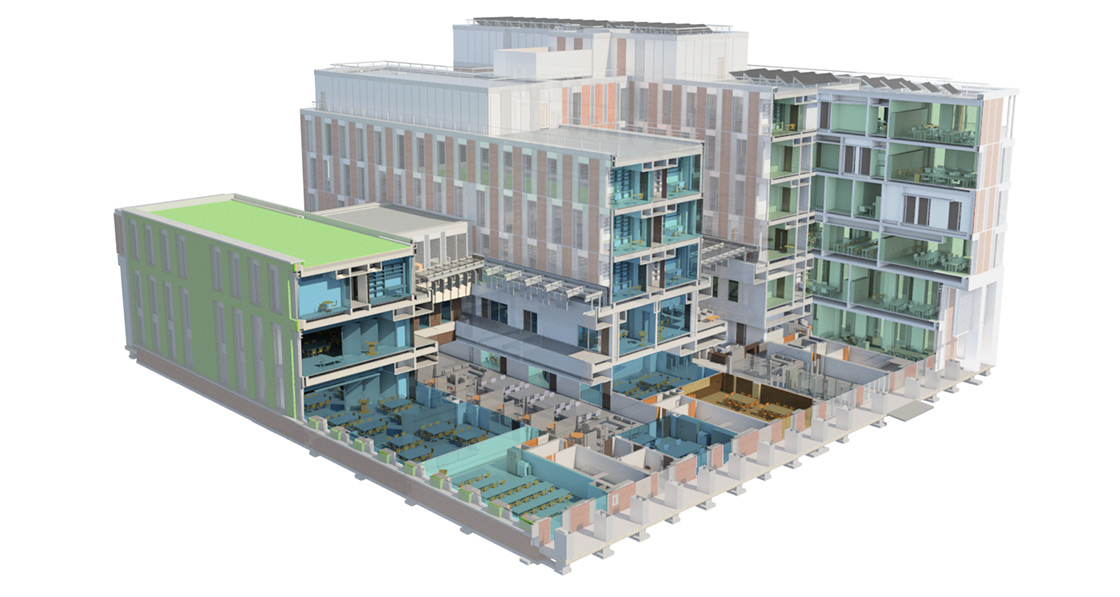

Cut-away computer-generated model showing the building’s structure and interior

But the building is far from the compact form that gives the best fabric efficiency. A two-storey block containing lecture rooms and communal facilities is surmounted by three slab-shaped ‘towers’ of different heights, up to six storeys altogether.

The relatively ‘non-compact’ form was driven by the brief, Jonathan Chadwick explains: “One of the key client requirements was that all of the departments being brought into the building should have equality of accommodation, so all of the offices are the same regardless of where they are in the building – this included those facing north: not great for heat loss obviously, but the University of Leicester were keen that the building would stand on its merits when judged against other criteria than energy use.”

A building this big makes distinct demands of the construction team, both because of the physical scale and weight, and because of process and oversight. An approach that works well for a small scale passive house project might not work so well at scale. “For example, insulated blockwork with parge for airtightness works fine on a small build, but it doesn’t really upscale to large buildings,” James Elliment argues.

The Centre for Medicine was procured on a design and build basis, so the construction approach was chosen by the contractor. The frame is of post-tensioned concrete, but rather than the architects’ original proposal of precast concrete panels, for the upper façade Willmott Dixon opted for high performance curtain walling, because it is light, reducing the size of the foundations required, and it tends to be relatively fast to put up.

However, while curtain walling is a well-established approach in the commercial sector, passive house levels of performance are not so well-established there.

“The standard systems don’t always offer the performance needed, so we specified a high-performance curtain walling system from Schueco, who are the ‘Rolls Royce’ of suppliers,” James Elliment says. Other aspects of the design, such as the shape with its relatively high surface area put extra demands on the thermal and airtightness performance of the walls. Additional insulation was needed, which in turn led to the need to fit a vapour control layer. As a result, the curtain wall turned out to be pretty labour-intensive to complete.

Airtightness too had to be exceptionally high.

Because of the increased fabric performance needed, in this building the team had to achieve an overall air change rate of 0.33 air changes per hour at 50 Pascals — a great deal tougher than the passive house minimum standard of 0.6. And airtightness is inevitably a challenge with curtain walling: “The system is basically hollow sticks of aluminium secured by lots of connectors, creating openings to be filled either with cladding or glazing. This involves lots of components, lots of seals and gaskets,” Elliment says.

Unsurprisingly this has the potential to lead to myriad tiny air leaks. “We really had to push it to get to the required airtightness level, it’s at the limit of what a curtain walling system can achieve.”

Glazing

Despite the performance disadvantages of floor-to-ceiling glazing in passive house, the offices nonetheless have full height windows. “From a purely passive house point of view the reasons probably aren’t very compelling!” admits Jonathan Chadwick. However, there are always other factors at play: “They add something to the character of the exterior and to the feeling of a room.”

The architects do recognise that you can have too much of a good thing, so added ceramic fritting (a kind of hard paint fused to the glass) at low level (below desk height), to provide privacy and reduce solar gains.

To limit unwanted solar gain, there are moveable solar blinds on most windows.

These are under the somewhat space-age sounding control of the BMS: “The blinds are controlled via an astronomical timeclock to track the solar path and linked to internal temperature monitoring,” Lee Davies of M&E engineers Couch Perry Wilkes explains, adding that users can manually override the controls, for example if they want to reduce glare.

Services

Like many other university campuses, Leicester has a district heating system, which powers the Centre for Medicine’s space heating via a mix of underfloor heating, and individually controlled radiators in the office spaces.

However, continuing to circulate heat outside the heating season, simply to supply hot water, can pose overheating risks. When, as here, hot water demand is low, a communal heat supply can also be very wasteful. For this reason Couch Perry Wilkes specified electric point-of-use heaters and water boilers for hot water. As Lee Davies explains: “This meant we could avoid the considerable heat losses you would get from long lengths of pipework throughout the building, minimising losses to ensure maximum efficiency.”

A big building obviously needs a big ventilation system, and as Couch Perry Wilkes explains, the contractor couldn’t locate anything that was officially passive house certified for the size and performance required. Instead bespoke air handling units (AHUs) were manufactured. Featuring a high-efficiency thermal wheel for heat recovery, these units were rigorously tested by BSRIA for thermal conductivity, air leakage and cold bridging.

Although the engineers report that it is not unusual with equipment of this size to need to commission bespoke units, there is an extra catch with passive house. Because the AHUs were not passive house certified an automatic efficiency penalty was applied, which the building had to ‘make up’ in other ways: “The AHU efficiency penalty was [another] reason more insulation was required, to improve U-values to compensate,” Davies explained.

Preventing overheating

In a small domestic building, the provisions in PHPP to calculate the overheating risk often represent an improvement on the hit-and-miss attention paid to the issue in this sector.

However in the mainstream commercial sector, with its high occupant densities, large amounts of powered equipment, and often, extensive glazing, analysis tends to be more sophisticated, and at the Centre for Medicine engineers Couch Perry Wilkes carried out dynamic simulation modelling. What’s more, PHPP shows 0% overheating for this building, says CPW’s Stephen Ball.

The Centre for Medicine does not have quite the extent of south glazing that besets some buildings, however high internal gains are anticipated from the 2400 occupants, and their equipment (including some distinctly old-school cathode-ray computer monitors that are on twenty-four-seven as part of a long-running research experiment).

Summer cooling is provided via manually operated vents in all spaces that are secure to the outside, plus automatic roof light openings in each of the building’s two Lamilux PR60 Energysave Passive House Institute certified glazed roof systems to discharge excess heat.

Two further strategies for cooling were included. There is provision for active cooling via the circulation of chilled water though the concrete frame. And on top of both these strategies, there is also a ground to air heat exchange system — an extensive set of pipes buried under the building, designed to pre-cool incoming air in the summer. This system can also pre-warm air in winter, when ground temperatures are higher than outside air temperatures.

The ground air heat exchange labyrinth was not easy to install, because, with the site being so tight, it had to fit right under the building, between the piles. Willmott Dixon’s James Elliment recalls: “If you can imagine threading 1.6 km of pipe around the piles and pile caps and all the other underground services…. There was a lot of discussion about whether to install the ground tubes before the piling – risking it being squashed by the piling plant — or after.

“We did the latter but ended up having to expose the piles to fit the tubes – even though the piles work by friction.” Because of the likelihood of condensation in the pipes during the summer, the whole system is carefully laid out with falls that drain to a sump, which is then pumped out. Microbial growth is mitigated by a silver lining to the tubes, and they will be regularly maintained.

Early calculations indicated that the system was expected to offer useful pre-conditioning around 40% of the time, explains Stewart Powell, engineer with the supplier Rehau — the rest of the time the advantage is marginal, and would not justify the additional fan power required to draw air through the system, so the BMS will switch the intake over to direct external air when this is the case.

Getting to know you

The design team are all signed up to a three year soft landings period. As Jonathan Chadwick explains, the design team is committed to work with the end-users and the estates team to fine-tune the building, and make sure that it’s being used optimally from an energy and comfort point of view. The building and the users are learning about each other’s behaviour, with a bit of adaptation on both sides.

(clockwise from top left) excavation of the site for the installation of the reinforced ground-bearing concrete slab; composite panels clad with a brick finish, with a 300mm cavity inside that was later insulated with Knauf Earthwool; facade mock-up panels at the facade engineer Wintech’s testing yard in Telford, built to test the buildability of the systems and iron out details like blind integration and airtightness; thermal bridge-free detailing, with masonry walls resting on thermal insulation; airtightness detailing with Pro Clima Intello vapour membranes; Rockwool mineral wool insulation batts fixed externally on the upper floors

The idea is that when this process is complete, the building will run pretty automatically at optimum performance. Most of the building’s systems work under an integrated system of controls, responding to both the weather outside and to indoor conditions such as CO2 levels and temperature. “This is key to effective building management and operation,” believes Lee Davies.

Some of these systems — local temperature settings, natural ventilation, and the movement of the solar shading — can also be controlled by users, but in a building with 2400 occupants, it was impossible for the design team to explain the systems to every user face to face, so inevitably it has taken a while for the users to learn how the building works, which in turn means it takes longer to tune the controls.

For example the office vents are designed to allow fresh air to cool the building at night in readiness for the next day, but as architect Jonathan Chadwick reports, there were “a few teething issues over the heights of summer when a small number of occupants complained about overheating in their offices.” The design team investigated the reasons for this as part of the soft landings process. Chadwick says: “It looks like a combination of factors — a series of very hot days, vent settings not being optimised, shading being overridden, openable vents not being used for night purging. Communicating this back to the staff is obviously a priority.”

Debbie Oldham is departmental manager at the Centre for Medicine, so works in the building: “It has taken us a bit of time to get used to the automated systems,” she says. “We are still learning to live in the building, there are a lot of different people to communicate with and explain things to.”

“People did keep asking ‘why can’t I just turn the light on? We are learning to get used to the lights coming on when you come into the room and dimming when the room is light enough, or the exterior blinds coming up and down of their own accord.”

While the engineers are proud of the way the automated systems have the potential to pare energy consumption down to the bone, it has been a learning process for the rest of the design team as well.

James Elliment of Willmott Dixon wonders if building automation could be overdone: “We know how we want the buildings to operate and how we want them used. We have given them a really intelligent building — we thought yes this is fantastic, but then you get an academic sitting there doing their research and things are going on and off by themselves, they find it annoying — which you can understand.” He concludes: “We have to learn from that, we have realised you can’t take all the control away from the occupants.”

The beauty of the soft landings process is that it is a process of mutual learning, Elliment adds. “These were not all things that we thought of beforehand, but this is what soft landings is for, we are tweaking and changing as we learn.” And meanwhile, the users, with all their individual perspectives, are learning too.

As academics the users are naturally curious, as Sarah Roberts, sustainable projects officer at the university, puts it: “They question everything!” The university staff and design team have now run several workshops for the users as part of the soft landings process. “We have done an awful lot of communication and it really did help.”

What about next time?

The successful achievement of passive house certification at Leicester proves that this size of passive building is possible in the UK. How easy will it be to repeat?

The total project cost of £42M included the university’s fit out and AV / IT installations, plus landscaping and other items. “When you strip these out and compare the construction cost alone then it seems very reasonable for the quality of the building,” Jonathan Chadwick believes.

The brief required the building achieve a BREEAM Excellent rating too, which added costs. “It has some benefits but how much it adds is a bit of a contentious issue,” Chadwick says. The extra-high fabric performance needed, and the construction of the ground air heat exchange system under the building, also added costs.

Quality control, so crucial to a passive house build, did pose challenges on such a big site.

One of the satisfying aspects of a successful small passive house build is the way it can liberate the existing ability of site crew to deliver really high quality work. This tends to flow from a fully ‘bought in’ site culture — not so easy to achieve when you have a large crew with, inevitably, much higher turnover, points out James Elliment.

“A lot of passive house is to do with quality control on site. In a small house with a small team you have more say in the choice of skill sets employed on the site, and it is relatively easy to monitor quality. This control is diluted on a big building, you need a much bigger labour pool and the management of that becomes harder. As an industry we have to face this challenge.”

With the curtain walling, for example, to get to the required airtightness level “you are really relying on workmanship”. But this workmanship is carried out by site crew, up on scaffolding — much harder to police. One option for large-scale passive house construction might be to take more of the construction off-site. “I think if you can reduce the number of areas sensitive to site workmanship, you are in better control,” Elliment believes.

“You can make a building more simple to build without it being a box. Certainly one of the great things about the Centre for Medicine is it is not a box, it’s a lovely building, it’s amazing architecturally.”

The Centre for Medicine was the second large passive house building Willmott Dixon had undertaken. The first, the Chester Balmore flats for Camden Council in north London, had been by everyone’s admission a pretty steep learning curve. Peter Warm, whose passive house consultancy Warm certified both, was impressed by the way Willmott Dixon took this learning forward. “I give the contractor full marks for putting in the effort from the start. Willmott Dixon did really well, handling the mismatches between what conventional engineering could give, and what passive house needed.”

“What’s great about this building is that it is integrating passive house into a large construction. Large scale passive house is pulling the large scale contractors into the requirements of passive house. You could see jobs like Leicester as stepping stones. But they made it, and have got a brilliant building.”

According to the calculations by the engineers, the finished building is expected to use around six to seven times less energy than the medical school’s previous accommodation, and monitoring will show if this is the case.

Despite any misgivings about the level of automation, Associated Architects have been delighted to discover how happy the users now are. “Overall the University’s project manager said that he’d never had so few gripes and phone calls from end-users after a building had been handed over, so we think this is a real positive for passive house and soft landings,” says Jonathan Chadwick.

“We’re proud that the building achieved passive house certification, and we think of it as a milestone for our practice and for passive house in the UK.”

Debbie Oldham is also delighted, saying: “I love the building, I feel really proud to be in it. The students like it too — at the moment the undergraduates are supposed to be out by 6.30, but they are requesting that we keep the building open later for them, as they want to stay!”

Perhaps the only way to get rid of them will be to build some passive house halls of residence for them as well.

Do design & build contracts work for passive house?

Although design and build has its fans, it’s a procurement approach that generates its share of gripes in the passive house world.

In design and build the main contractor takes on the building mid-way though the design process, so they do have more chance than in a conventional build to input into the design. However, problems can arise when the client employs designers to carry out a concept design to go to planning, and then invites contractors to price for completing the design and constructing the project. At this point many details are set in stone, and it may be too late for the contractor to optimise the basics of the design, but they are still responsible for meeting the passive house specification, and bearing the costs of any late changes needed to reach this.

Because designers and contractors are not working together from the off, the design team misses the invaluable input from builders to help make the designs buildable. Meanwhile, the designers may lose control of crucial aspects of the finished building, especially if they are not taken on by the contractor for the build phase.

James Elliment of Willmott Dixon says: “You usually end up with the contractor and their supply chain doing a lot of the detailed design, but with this contract arrangement, the lead time is really short, because you don’t start procuring these designs until you’ve got the contract. For the Centre for Medicine we signed the contract, and four weeks later we were starting on site, and still procuring designs as we went along.”

Jonathan Chadwick of Associated architects agrees that even though in the end it worked out fine here, the arrangement was not ideal. “If we did it again we’d ensure that design development periods were sufficient, and specialist subcontractors appointed early enough.”

James Elliment says he is not against two-stage or ‘negotiated’ design and build contractors for passive house, as these allows the contractor to influence the design, but is not in favour of one-stage tenders, which preclude the contractor from doing so.

“I am completely converted to passive house but I am concerned that the industry won’t take it up if contracts aren’t let the right way. If contractors are left with a lot of the risk then they will be nervous, and their perceived premium will increase. This won’t be good for passive house.”

Elliment favours instead a collaborative framework approach, with open cost planning. “You can design it together, so the whole thing can be well thought through, and everyone has some comfort about costs and risk.”

Selected project details

Architects: Associated Architects

Main contractor: Willmott Dixon

Project management: Bidwells

M&E engineering: Couch Perry Wilkes Partnership

Civil & structural engineering: Ramboll

M&E contractor: NG Bailey

Passive house certification: WARM

Ground air heat exchanger: Rehau

Cost consultants: Gleeds Worldwide

Landscape design: Gillespies

CDM co-ordinator: Ridge

Approved inspectors: Approved Design

Planning consultant: RPS

Breeam assessor: HRS

Curtain walling (contractor): Advanced Glass Facades

Curtain walling (supplier): Schueco

Glazed roofs: LAMILUX UK Ltd

Green wall: ANS Global

Composite cladding: Skygreen / Kingspan Benchmark

Glass balustrades & fixed solar shading: Scala Vetro Partitions

Ceilings (suspended): Global Contract Interiors

Plasterboard ceilings & partitions: Reynolds

Acoustician: Cole Jarman

Roofing: Briggs Amasco

Insulated render: Intastruct

Tiling: WB Simpson

Brickwork: Ibstock

External insulated render: Marmorit

Solar PV: GMI Energy

Additional info

Building type: 12,800sqm (gross internal floor area) 2-6 storey detached concrete framed teaching and research facility for the College of Medicine at University of Leicester.

Location: University of Leicester, Leicestershire, UK

Completion date: January 2016

Budget: Construction cost approx £29M, total project cost including VAT, FF&E, AV/IT, fees and landscaping approx £42M

Passive house certification: Certified

Space heating demand (PHPP): 15 kWh/m2/yr

Heat load (PHPP): 11 W/m2

Primary energy demand (PHPP): 116 kWh/m2/yr

Environmental assessment method: BREEAM – Excellent rating

Airtightness (at 50 Pascals): 0.33 ACH

Energy performance certificate (EPC): A:19

Thermal bridging: Thermal bridges for capping support brackets, balustrade support brackets and curtain walling support brackets were modelled and quantified, pile caps insulated on all sides, thermal breaks to all steelwork connections, low conductivity TeploTies to cavity masonry, Foamglas loadbearing insulation to base of masonry.

Ground floor (typical construction): 22mm terrazzo tiles on decoupling mat, on 70mm floating screed, on 30mm Knauf Polyfoam Floorboard Eco Extra insulation, 150mm ground bearing RC concrete slab on 65mm Knauf Polyfoam C350SE insulation. Average ground floor U-value 0.250 W/m2K

Walls: Various constructions – average U-value 0.130 W/m2K

Lower floors typically: 103mm Ibstock Cheddar Red brickwork externally, followed inside by 300mm cavity with Knauf Earthwool Dritherm 32 Ultimate mineral wool insulation, 140mm medium density blockwork, 13mm wet plaster internally.

Green wall: Green wall planting modules externally on treated timber battens, followed inside by breather membrane, 100mm medium density blockwork, 300mm cavity with Knauf Earthwool Dritherm 32 Ultimate mineral wool insulation, 140mm medium density blockwork, 13mm wet plaster.

Upper floors typically: PH certified thermally broken Schueco curtain walling system with brick slips externally, followed inside by carrier boards fixed to insulated spandrel panels, 25mm air cavity, 100mm Rockwool Duoslab mineral wool insulation, 150mm Rockwool Duoslab mineral wool insulation, vapour control layer, IWL plasterboard studs with two 15mm plasterboard layers, and skim finish. Roof, typical construction: Paving slabs on spacers / pebble ballast, on separation layer, on 270 / 410mm Jablite Premium Flat Roof Inverted insulation, on hot melt roof waterproofing, on 250mm RC concrete slab. Average roof U-value 0.130 W/m2K

Glazing: Schueco PH certified triple-glazed curtain walling with argon filling and an overall U-value of 0.75 W/m2K (average) Passive House Institute certified Lamilux PR60energysave triple-glazed glass roofs to east and west atria. Overall U-value 0.82 W/m2K

Heating system: Connection to University of Leicester CHP district heating system for space heating. Electric point-of-use heaters and water boilers for hot water.

Ventilation: Bespoke Barkell air handling units with heat recovery, tested by BSRIA at 74% efficiency

Electricity: 115 square metre 30kW solar PV array Green materials: Post-tensioned concrete frame to reduce the total volume of concrete, TABS embedded soffit cooling within concrete structure, Rehau ground-air heat exchange with 1.6km long pipework labyrinth buried beneath the building, green / brown roof and living wall to increase site biodiversity, Schueco CTB external shading blinds.