- Design Approaches

- Posted

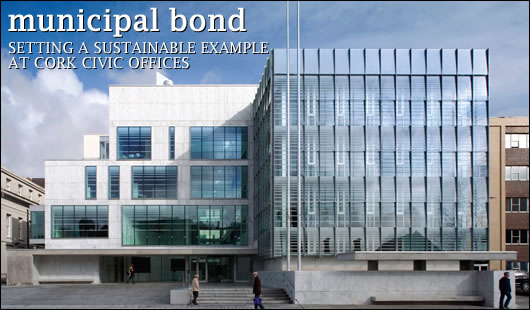

Municipal Bond

If the Irish construction industry is truly to rapidly embrace the concept of sustainability, leadership from the public sector will be paramount in setting the right example. John Hearne spoke to the design team of the Opus and RIBA award-winning Cork Civic Offices, a development which keeps carbon emissions and fossil energy consumption to a minimum, and once more puts the public sector at the forefront of innovative sustainable design

In commissioning the new Civic Offices in Cork, the local authority knew exactly what was needed. Sufficient space to draw together the disparate offices scattered throughout the city was vital. The new structure had to blend sympathetically with the existing 1930s classical building. And, of course, it shouldn’t cost the earth to run.

Three years and e35m later, the suite of design awards testifies to building’s aesthetic achievements. Less obvious is the high level of sustainability engineered into almost every aspect of that design. Eco-friendly materials combine with a highly innovative natural ventilation strategy, geothermal heating and low energy lighting to create a vital public space at the heart of the city. ABK’s John Parker headed the design team in what amounted to a design, build and finance contract. He explains that while the City Council issued a comprehensive brief, it wasn’t overly prescriptive. “In principle,” he says, “there was a fairly high importance placed on sustainability in the design. We were coming to the competition with that state of mind already. It’s ingrained culturally within the office, within the team.” The project brought ABK back to together with consulting engineers Homan O’Brien, with whom they had worked on the development of the award winning Offaly Civic Office Building in Tullamore and the North Tipperary Civic Offices in Nenagh. In arriving at a practical sustainable solution in Cork, the team drew heavily on their experience in these earlier jobs. “It was very much a common language and common approach.” says Parker. “There are similarities in terms of the strategy. Although it’s a different project…you don’t reinvent the wheel. I see the Cork project as a refinement of some of the technologies and approaches that are used in Offaly. It was a variation, or a development on a theme.”

“You tend to look at what other people are doing and what you’ve done before.” Brian Homan agrees. “It’s almost like a continuous development of an idea, a reworking of an idea.”

The Cork project however presented a number of unique challenges. In order to meet ambitious occupancy targets, and working within tight height restrictions, the team had to maximise site coverage. Adaptability was also an issue. “The building has to work on two faces.” says Parker. “As an extension for the city offices and also as a potentially lettable office development. As a result, it’s a very dense development. There’s a main body of office space which is contained within a glass volume and then there’s a kind of an L-shaped leg that comes off the back of the building and that forms the edge onto Eglinton Street. That has its own separate entrance if they decide to rent that out and the council can extend into that leg, or retract down it as they need to, so the building is appropriately flexible to suit their needs over time.” All open-plan office space runs along the inner perimeter of the building in order to make best use of the natural daylight, with meeting rooms and toilets placed at the centre, the ‘dark side’ of the plan. Links have been created between the new and old buildings at ground and first floor levels, where the new structure wraps itself around what had been the external façade of the older building’s concert hall. A central atrium, seven metres wide and five storeys tall, floods the departments below with natural light. This space, the atrium, is central to the public life of the building. “What we had noticed on the site,” says Parker, “is that people were parking in the adjacent multi-storey car park and walking diagonally across the site to head into the city centre. We noticed this diagonal route that people were taking, and we kept that in the building. From nine to five when people head into town, they walk in through the building and out the other end. It’s like a street within the building. The design picks up on little things that are happening there already and takes advantage of them.” The bus stop integrated into the new building is another exercise in drawing existing civic space into the design. This was an attempt, says Parker, to redeem the necessary evil of a carpark on the roof. “We decided that it would be a wonderful thing if the building became a bus stop for the city. So we designed the building with a monumental bus stop. The building stems out and forms a stone-clad bus stop so that now everyone who goes to City Hall gets off at the City Hall bus stop, which is part of the building. The idea was to tie the building into an idea of public transport. People now talk of it as an address within the city.”

The real innovations however lie in the blend of technologies and techniques which modulate living conditions within the building. According to the original environmental strategy, “when compared with a standard air-conditioned office building, our energy consumption will offer a 300% plus reduction in running costs.” The building’s total energy requirement is estimated at 133kWh/m2/a, with carbon emissions of 65 kg C02/m2.

The heating load is borne primarily by a series of vertical bore collectors located in the basement, linked to a heat pump in the plant room and connected to a system of pipework embedded within the building fabric. “Our building is built basically on marshy salt bog.” says Parker. “Below it there is sea. Essentially, we’re extracting water from the tidal estuary of the Lee which is underneath the building. The council had originally identified this as a potential heating solution that we might tap into. Similar to what we had done in Offaly, we cast heating and cooling pipework into the exposed concrete slab, with the proposal that the slab in winter would be used as a giant radiator and in summer would be used as a cooling surface.” One thing that no one appears to be able to explain is the astonishingly high temperatures – up to 17 degrees – which the vertical collectors have been extracting. “That’s the one thing that surprised us big time.” says Brian Homan. “It’s great for heating in winter. When you get the temperatures of the source and the sink close together, your coefficient of performance will go right up, so in winter you’re really flying, and if you’re doing it at half-price night-rate electricity, you’re double flying.” The downside of course is with such high temperatures coming from the boreholes, the efficiency on the heating side is countered by inefficiency on the cooling side. The design team believes however that because the heating load of the building is more onerous than the cooling load, the advantages of those high source temperatures outweigh the disadvantages. The heatpumps themselves are two Blue Box Omega 701 HP water to water units, with a cooling capacity of 224kW and a heating capacity of 214kW.

The embedded pipework cast into the exposed concrete slab is Pecs A crosslinked polyurethane, supplied by VCS in Dublin. “When heating,” says Bob Daly of VCS, “you’re sending the water through at approximately 35Co or 45Co. In cooling you’re sending the water through at a much lower temperature…You would have then humidity stats and air temperature stats to make sure that the temperature in the space doesn’t go below approximately 16Co, because if it does you get condensation occurring on the slab and throughout.” The thermal mass of the concrete builds, as Homan suggests, through the night. In set-back mode through the day, the slab gives up its heat into the office space. The heat pump is also supplemented by two 1,033kW gas boilers. A drastic over-specification at first glance, the new boilers have replaced an antiquated oil boiler which had provided heat to the old building. Three quarters of the gas boilers’ capacity now serves the original building.

Undoubtedly the most innovative element of the environmental profile is the ventilation. To minimise the use of mechanical ventilation in the building, the design team came up with a system that actually harnesses wind power. Two wind-cowls on the roof channel the air through chimneys that cross the atrium roof to deliver fresh air into the office spaces. Because you’re dealing with a low velocity system, John Parker explains, you need much larger duct work, particularly in those areas farthest from the cowls. “The services and the architecture begin to make the building.” He says. “We have these very deep chimneys that span the atrium and form a very thick wall to one side of it. The profile of the concrete slab changes according to the amount of air that is pushing around the place, so in the middle of office plan we have a very deep floor void and a lower office ceiling. Then the ceilings tilt towards the light to maximise the amount of daylight into the building, producing above the ceiling a tapering or a stepped floor void because we need less and less air as we head towards the windows.”

A heat exchanger is used to ensure no loss of heat energy through the process. “Air goes from the offices out into the atrium,” Brian Homan explains, “then back into the air handling units through grilles at high level in the atrium…There’s a thermal wheel, a big wheel that’s slowly going round all the time in the air handling unit, so as the air is going out, it heats up the wheel, which preheats the air coming in.” Mechanical ventilation is used in the ‘landlocked’ side of the building, where the toilets, meeting rooms and comms rooms are all located. “In the air handling unit as well, in summer, on the return air, there’s a spray.” says Homan. “We spray water at the return air and what that does is it cools it right down to dew point, and then that cool air goes into the thermal wheel and then it actually pre-cools the air that’s coming in.” When the wind isn’t strong enough, pressure sensors in the AHUs turn on fans which then deliver fresh air where it’s needed.

Alternatively, you can just open a window. John Parker explains that the building’s double façade facilitates this simple empowerment, one of three reasons why it was designed in. “One was to act as a baffle for wind. We’ve done projects before where they’ve done opening windows and in Irish weather they’re very inappropriate, you find that you crack them open a millimetre and you end up with a gale coming in. Unless the windows are very well designed, they’re very inappropriate for Ireland, so part of it was to control the amount of ventilation, to provide a baffle between inside and out. The second reason was solar control… The outer glass façade has this fritted pattern on it. That cuts out an awful lot of the solar gain into the building. What’s good about it is it doesn’t limit the amount of daylight. It’s a slightly more subtle way of getting light into the building.” The third rationale for the double façade lay in the fact that it offers an acoustic baffle against city noise. Other elements of the architecture have found secondary uses too. In the roof of the atrium, the chimneys used in the natural ventilation strategy double as sunshades. “You don’t get too much glaring sun into the atrium.” says Parker. “Its long side faces south, so as light comes in from the south and hits the opposite wall - which has got virtually no windows in it – that big white wall acts as a reflector. It bounces the light down into what is actually a very narrow space. The atrium is about 5 storeys high, but it’s only 7m wide. You would have thought it would be very dark but it’s very bright.”

Originally, the concrete structure of the building had been specified in conventional concrete, with Ecocem’s GGBS specified for the basement. “That was because of the saline, the aggressive salt water conditions of the basement.” says Parker. “GGBS is more stable. Because of its chemical constituents, it doesn’t react so much with salt water. Basically it’s a better solution from an engineering point of view. But it provided an amazing reduction in carbon emissions, so we went to the contractor and we asked him would he use it for the whole project. It was roughly the same price, so we managed to get it for the whole job.” The building uses almost no timber. Besides extensive glazing, the front façade is cladded with Carrara marble. While indigenous stone possibilities were researched, the marble was picked because it is particularly sympathetic with the local limestone used on the original building, limestone which is no longer quarried. “There’s also an ease of disassembly.” says Parker. “If you look at the façade, it’s all bolted together and can be easily disassembled into its constituent components. It’s all galvanised steel flats and flues.” Sustainability is once again the rationale here. “Rather than having to knock the thing down, you can go up and take it apart and reuse or recycle it away in the long term.” The building fabric delivers U values of 0.22 in the roof, 0.35 in the walls and 1.2 in the glazing.

“From the point of view of the lighting system,” says Mark Wilson of Malone Lighting, “the cast concrete of the building meant there were no facilities for the contractors to incorporate recessed luminaries or to have any sort of surface wiring facilities, so the lighting system that we provided is a suspended rail system and the rails that the light fittings were suspended on also acted as the cable containment.” The system uses T5 high efficacy lamps which deliver high lumin output per watt. “It’s a fully automated presence and daylight controlled system. So if it senses that there’s someone working in the area, it will stay on, and at the same time it senses the amount of daylight in the area and regulates down dependent on that.” While manual override is possible in particular circumstances, the system is hardwired to revert to its preprogrammed settings in order to deliver maximum energy savings while providing optimum working conditions. “It’s simple but at the same time highly effective.” says Wilson. “We would expect to see energy savings on the lighting of 50% plus over a non-dimming, non-sensor system. If there were no controls put in there at all, those are the kinds of savings we would expect to see.”

Architect John Parker believes that the combination of technologies and solutions blended into the civic offices represents a reversion to the guiding principles that obtained before we developed our oil habit. “Up until the 1950s in Europe, you always designed a building in a practical sustainable way. You had to deal with a lot of things that the provision of oil subsequently mitigated.” He points out that the reliance on mechanical ventilation is a relatively new thing. These new directions facilitate a re-engagement with the office environment by the people who use it, the people who exist at the locus of good design and sustainable practise. “For us providing a building that can give fresh air, a well tempered environment and decent day-lighting is part of the task of making a good office environment.”

Project details

Client: Cork City Council

Architect: ABK

Consulting engineers: Homan O’Brien

Air handling units: RMI

Geothermal heat pumps: Walkair

Controls: Standard Controls

Lighting: Malone Lighting

Embedded pipework: VCS

- Articles

- Design Approaches

- Municipal Bond

- Cork Civic Offices

- geothermal heat pumps

- Embedded pipework

- Air handling units

- Homan OBrien

- Walkair

Related items

-

Steeply sustainable - Low carbon passive design wonder on impossible Cork site

Steeply sustainable - Low carbon passive design wonder on impossible Cork site -

Focus on whole build systems, not products - NBT

Focus on whole build systems, not products - NBT -

International - Issue 29

International - Issue 29 -

Passive Wexford bungalow with a hint of the exotic

Passive Wexford bungalow with a hint of the exotic -

The House of Tomorrow, 1933

The House of Tomorrow, 1933 -

1948: The Dover Sun House

1948: The Dover Sun House -

The dazzling Dalkey home with a hidden agenda

The dazzling Dalkey home with a hidden agenda -

Mayo passive house makes you forget the weather

Mayo passive house makes you forget the weather -

A1 passive house overcomes tight Cork City site

A1 passive house overcomes tight Cork City site -

Norfolk straw-bale cottage aims for passive

Norfolk straw-bale cottage aims for passive -

Time to move beyond the architecture of the oil age

Time to move beyond the architecture of the oil age -

West Cork passive house raises design bar

West Cork passive house raises design bar